Cybersecurity

Defense-In-Depth: Cybersecurity

Feb. 10, 2023

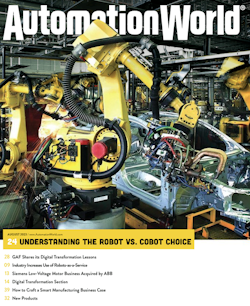

Robotics

Robotic Technology Use Across Industry

Nov. 1, 2022

Home

Learn more about MOXA switches

Nov. 1, 2022