Before I began covering the manufacturing automation industry in 2003, I spent a decade covering technology developments in the manufacturing enterprise systems space. At that time, ERP systems were largely reserved for big companies with huge capex allotments and the in-house IT resources to support the system’s implementation and maintenance.

But as ERP systems became more affordable and expanded throughout much of the manufacturing industry, an interesting thing happened. The factory floor and the front office became directly connected. This happened largely so that front office systems like ERP could access shop floor data to deliver greater levels of business intelligence and enable better decision-making throughout the company. Beyond the software and operational implications of this trend, the conversion to Ethernet as the de facto factory floor networking option was another huge result of the manufacturing industry’s adoption of ERP.

Now, as more companies look to invest in technologies after sitting on the sidelines during the recession, a new trend appears to be developing that could have just as big an impact on factory floor engineers and operators as the initial wave of enterprise systems did nearly 20 years ago.

According to a study conducted by Plex Systems and the Manufacturing Performance Institute (MPI), many manufacturing executives now “find their firms constrained by aging facilities, failure-prone equipment, and outdated software and systems.” These findings support the results of another recent study that noted 40 percent of enterprise resource planning (ERP) systems are now more than seven years old, and 7 percent of ERP systems are more than 15 years old.

Yes, Plex Systems is a provider of ERP systems, so it’s not a big surprise that a study they had a hand in developing would show potential for ERP growth. Despite this, the findings noted in their study with MPI are not contrary to what other industry trends are indicating. Considering the greater trends currently taking place across industry—ranging from a focus on greater levels of intelligence for executives as well as operators to a higher level of adoption of cloud-based operating systems—many of the Plex/MPI report findings appear to be in line with clearly evident manufacturing trends.

Some of the principal results of the Plex/MPI study include:

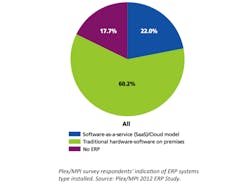

• A majority of manufacturing respondents (60 percent) indicate they operate a traditional ERP system in which hardware and software are on premises; 22 percent operate a software-as-a-service (SaaS)/cloud ERP system; 18 percent have no ERP system in place.

• Lack of an ERP system is highest among companies with lower annual sales: 26 percent of organizations with sales of less than $50 million have no ERP.

• Two-thirds of cloud ERP users (68 percent) have unlimited licensing agreements within their companies, more than double the percentage of traditional ERP users with unlimited company licenses.

• These licensing agreements impact the number of employees who can access ERP: 90 percent of employees for cloud ERP users vs. 30 percent for traditional ERP users.

• Cloud ERP users are significantly more likely to make their systems accessible to suppliers (60 percent cloud vs. 14 percent traditional) and customers (43 percent cloud vs. 11 percent traditional).

Having witnessed the impact that software technologies such as ERP have had on the manufacturing industries, I think it’s fairly evident that we’re on the cusp of another surge in technology-driven developments for the industry as a whole. In fact, the lower costs of cloud-based ERP will likely drastically reduce the number of manufacturers without ERP over the next few years.

By democratizing access to information across all levels of a company, cloud technologies are already changing manufacturing. It looks like the biggest changes will come as the cloud enables more players in the supply chain to take part in optimizing the manufacturing process.

Considering how inexpensive and ubiquitous the technologies that will enable this have become, I don’t suspect this next foray in industry connections will transpire over the next 20 years. It will happen much faster.

Learn more about how cloud computing is impacting manufacturing today at The Automation Conference in Chicago, May 14-15, 2013. Presenters addressing the impact of cloud technologies on industry include: Kai Mariappan from Coca-Cola, Mitch Free from MFG.com, and Arnav Anand from UC Berkeley.

Leaders relevant to this article: