I’ve always thought of M2M (machine-to-machine) connectivity as a very manufacturing-centric concept. Though the term M2M is often used interchangeably with the Internet of Things (IoT), when I hear M2M I tend to think in terms of manufacturing equipment connected to a network for bilateral communication. With IoT, however, I think of connecting any kind of device to the Internet for an endless array of communication options. This viewpoint certainly stems from the focus of my job; but regardless of the reason for my error in thinking, it turns out that the manufacturing industry could be a real laggard when it comes to M2M application compared to other industries.

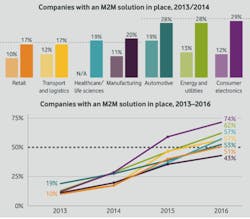

According to the “M2M Adoption Barometer” study conducted by Circle Research for Vodafone, the global telecommunications company, three sectors have emerged as front-runners in M2M with nearly 30 percent adoption rates—automotive, consumer electronics, and energy and utilities. With a 20 percent adoption rate, manufacturing lags well behind the three front-runner sections.

The study results are based on surveys of more than 600 executives involved in setting M2M strategy in seven industries across 14 countries. (Note: If you’re wondering why a company like Vodafone is so focused on a topic like M2M, remember that it’s the networks they manage and connectivity services telecommunications companies like Vodafone provide that enable transmission of the data in M2M/IoT applications.)

When I first saw the chart in the Vodafone study, I have to admit I was a bit confused. After all, in my way of thinking, the automotive and consumer electronics industries are manufacturing industries. The Vodafone report authors seemed a bit confused by this as well, who noted that they expected “manufacturing to put in a stronger showing.” They attribute this discrepancy to one of two possibilities: 1) manufacturers with more “ambitious M2M plans tended to categorize themselves as being in other sectors, such as consumer electronics, automotive or even healthcare” rather than “manufacturing”; or 2) some respondents don’t consider what they’re doing, e.g., production line monitoring, as M2M because they’ve been doing it for years and think of M2M as a relatively new technology development.

Further muddying the picture is how the study classifies the reasons behind the leading status of the automotive and consumer electronics industries when it comes to M2M.

According to Vodafone’s analysis: Automotive “OEMs and their partners have continued turning the car into a connected platform, supporting a wide range of services. The premium sector is now well established and M2M is seen as an enabler for very valuable services for manufacturer, dealer and driver alike…such as remote maintenance and infotainment.”

As for consumer electronics, the Vodafone report states: “Consumer electronics firms have already embraced the connected device, building M2M into the products they sell. And we expect them to increase their lead, with nearly three quarters of firms adopting M2M by 2016. We attribute this to greater consumer awareness of the potential for connected devices, such as thermostats and kitchen appliances.”

In both cases detailed above, M2M figures into end use applications of the products (be they automotive or consumer electronics) but not necessarily into the manufacturing processes used to create them.

Though the picture may be unclear here about production uses of M2M versus product end use applications, one thing the study made very clear is how quickly M2M use is accelerating.

The study compared responses gathered in 2013 with those gathered in 2014. In that one-year timeframe, the study found that M2M adoption has increased by more than 80 percent globally, leading to a prediction that more than half of companies in the Americas will implement M2M by 2016. In automotive, use of M2M increased from 19 percent to 28 percent between 2013 and 2104; in consumer electronics it went from 12 percent to 29 percent; in energy and utilities it went from 13 percent to 28 percent; and in manufacturing it went from 11 percent to 20 percent.

And these numbers are expected to continue skyrocketing upward. Vodafone predicts that, by 2016, the consumer electronics industry will have a 74 percent adoption rate and manufacturing will reach a 43 percent adoption rate. Despite those considerable growth rates, manufacturing will be at the bottom of the M2M adoption rate in 2016, according to the study. Not only will it be outpaced by automotive, energy and utilities and consumer electronics, as it is now, but healthcare/life sciences, transportation/logistics, and retail are all expected to move ahead of manufacturing in terms of M2M adoption.

To reiterate, some of this differences between “industries” in this survey could be exaggerated based on how companies identified themselves for the survey. However, it nonetheless points to a lagging position for the deployment of M2M/IoT capabilities in manufacturing compared to more consumer-facing applications.

Whether you prefer the term M2M or IoT, it’s clear that the applications of the technologies involved are quickly moving beyond the concept stage in industries across the globe. As Matt Hatton, principal analyst at Machina Research, said of the survey results: “The most interesting finding from my perspective is the range of different reasons companies are giving for deploying M2M. Historically, M2M technologies have tended to be bolted on to add an additional cool product feature or to monitor some kind of internal process. We now see M2M is becoming fundamental to how organizations do business; in some cases, M2M adoption is also creating new business opportunities. These technologies are radically changing the way in which companies serve—and communicate with—their customers.”