With continuous improvement pressures and China's recent economic slowdown, analysts are becoming more bullish on Chinese manufacturers expanding factory automation investments and, in particular, robotics. Morgan Stanley (www.morganstanley.com) recently released a Blue Paper, entitled, China - Robotics: Automation for the People and it includes growth factors, industry analysis, and possible scenarios for automation suppliers.

Even with a tepid 2012 for China, Automation World continued to see the trend of robotic suppliers move operations to China. Robotic automation is seen by many as low-hanging fruit and the reasons why are: 1) Plant managers used to see automation and its associated depreciaton equipment costs as a negative; 2) Automotive industries are requiring more standardization; and 3) rising wages and elderly population.

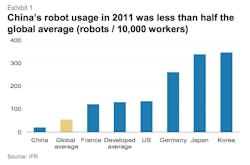

The reports point out that "robot usage some is 60 percent below the global average, a market of $1.2 billion today could be worth $6 billion by 2020–a five-fold increase." It goes on to suggest that even though China robotics demand today is small at $1.2 billion last year, on a relative basis its share of total automation spend is actually quite high at 27 percent, compared with the global average of close to 4 percent. The reports project that China’s robot usage effectively catches up with the global average of 55 robots per 10,000 workers (adjusted for GDP/capita), and then the market could easily reach $6 billion. This would still be a long way short of usage in Japan and South Korea at 343 per 10,000 workers.

The report also provides a detailed analysis of four automation supppliers in China: ABB (www.abb.com); Fanuc (www.fanuc.com); Yaskawa (www.yaskawa.com); and KUKA Robotics (www.KUKA.com). Adept Technology (www.adept.com) is referenced for its 128 SCARA robots used in a Philips application and, of course, automotive is presented by KUKA and its 330 robots in building the Mercedes A Class sedan. China robotics are still heavily dependent on the automotive industry with 59 percent of demand, relative to electronics at 17 percent.

Other key findings include:

• The paper compares the current situation in China with developments in Japan during the 1970s and 1980s. The parallels are both relevant and compelling. In Japan: (i) the nature of the workforce and rising wage pressures are a meaningful factor; (ii) ‘cultural drivers’, in terms of willingness to displace workers and adopt technology are meaningful also; (iii) quality issues become important, as a domestic industry evolves; and (iv) growth rates, as robot penetration occurs, can be quite spectacular during the ‘ramp-up’ phase.

• Machine tools accounts for 11% of the total demand. In Exhibit 38, we have compiled IFR data using 5-year average robot shipments by sector. We have segmented the shipment data into three key industries: automotive, electronics and metals (though note that there are other applications in plastics, chemicals, glass, construction and other industries).

• China could reach 50 robots per 10,000 workers in applications outside of automotive. As Exhibit 67 suggests, this is again not a demanding target and would make its usage ex-auto similar to that of France currently, but still ~65% below the current average for these applications. Robotics are used significantly in assembly functions in advanced electronics but also in many types of industrial machinery and machine tool applications.

• China and South Korea are mirror images in auto and electronics demand. We find this point very interesting, because it tends to suggest the following: (i) that China’s robotics market is still in its infancy, and is disproportionately dependent on the automotive industry; (ii) that in more advanced economies such as South Korea and Japan, robot applications are far more broad-based.

• Automotive industry is nation-wide, not just coastal. The production of motor vehicles is widespread throughout the country and the top seven provinces in terms of vehicles output only concentrates. 60% of the total production.