KUKA KR Quantec PA Arctic Series of Palletizing Robots

KUKA Robotics Corporation introduces the KUKA KR Quantec PA Arctic Series of Palletizing Robots. No suits, no bags, no robot protection is needed for the KR QUANTEC PA Arctic Series to endure temperatures as low as -30°C. The KR QUANTEC PA Arctic Series is an ideal fit for the refrigerated, frozen food and beverage markets with availability in 3 payloads of 120 kg, 180 kg, and 240 kg with a reach of 3,195 mm makes them perfect for all kinds of frigid lifting!

The KUKA KR 3 AGILUS

The new KR 3 AGILUS is the latest robotic breakthrough that redefines the 3 kg class by setting new standards and mastering various tasks with agility, precision, and flexibility even in extremely narrow spaces. The KR 3 AGILUS is one of the fastest robots in its class offering minimum cycle times and larger production outputs. This small robot even makes it possible for simple and cost-efficient cell concepts thanks to its low weight, compact design, and flexibility.

Introducing KUKA.PickControl

KUKA's new PickControl software combines conveyor tracking and image recognition to locate, track, pick, and place parts from moving conveyors. A major feature of this technology package is load sharing, which allows the workload to be distributed among multiple robots as the user sees fit. This helps to meet the needs of different production scenarios, for example, dealing with peaks in production. The application meets the requirements posed by the logistics and consumer goods sectors, but is also suitable for other industries and tasks.

About KUKA

KUKA is one of the world's leading manufacturers of industrial robots. The robots range from 3 kg to 1,300 kg payloads, and 540 mm to 4,000 mm reach, all controlled from a common PC based controller platform. KUKA robots are utilized in diverse range of industries for packaging & palletizing, such as consumer goods, food, beverage, and pharmaceutical.

COMPANY OVERVIEW

COMPANY OVERVIEW

About KUKA Robotics Corporation

KUKA robots are utilized in a diverse range of industries including the food, beverage, consumer goods, logistics, pharmaceutical, medical,and plastics industries as well as multiple applications including material handling, packaging, palletizing.

Product Summary

Industrial robots, controllers, software, linear units,omni-directional motion platforms.

Contact

22500 Key Drive

Clinton Township, MI 48036

United States

http://www.kuka.comClinton Township, MI 48036

United States

866/873-5852

866/329-5852

More Info on KUKA Robotics Corporation

More Info on KUKA Robotics Corporation

Featured Videos

Featured Videos

How to KUKA.AppTech: Home2Home

April 15, 2024

Webinar: Accelerating Arc Welding with KUKA.ArcTech

April 11, 2024

Products & Press Releases

Products & Press Releases

Home

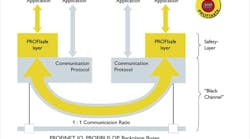

Industrial Ethernet: Diagnostics

Feb. 26, 2014

Articles & News

Articles & News

Analytics

Turbocharging Speed to Market

Oct. 10, 2022

Videos & Resources

Videos & Resources

Request More Information

Request More Information

All content from KUKA Robotics Corporation

All content from KUKA Robotics Corporation