As an editor, writer, musician and home beer brewer, I tend to lean more toward right brain, creative, artistic projects. Despite this inclination, for as long as I can remember I have been fascinated with technology and scientific advances of all kinds. And the past few weeks have produced the kind of technology news I love to learn about. I’m writing about them here not just because I find them interesting, but also because these advances will almost certainly impact the manufacturing and automation space.

The first of these breakthroughs I learned about was the graphene supercapacitor. Discovered by a team of UCLA scientists, this carbon-based supercapacitor is essentially a rechargeable battery capable of being recharged in a fraction of the time required by current batteries. To clarify what I mean by “fraction”, the researchers expect these supercapacitors, when used in devices like smart phones, to be capable of being fully recharged within seconds. As for electric vehicle batteries, they expect them to recharge in the space of a minute—faster than it takes to fill you car up with gas.

And since the graphene supercapacitor is completely carbon based, there is no concern with disposal. In fact, Richard Kaner, head of the UCLA research group that discovered the supercapacitor, says that spent supercapacitors no longer capable of being recharged can be broken up and used to feed gardens.

See a video about this technology at the bottom of this article.

News of this technology advance has been out for a little more than a year now, but it re-entered the news cycle recently with news from the UCLA researchers, and reported in Nature Communications, that the graphene supercapacitor fabrication process has been made more efficient. This means that the concept is already proving to be scalable beyond the initial simple yet time-consuming production process. The initial process involved coating blank DVDs with a liquid graphene substance and then exposing it to the laser light in the DVD dive.

While the electric car battery supercapacitor application may still be years away, the researchers are already in discussion with industry partners to bring the graphene supercapacitor to bear in applications ranging from roll-up displays and TVs to e-paper and wearable electronics.

According to Kaner, the supercapacitors can also be directly integrated onto chips to better extract energy from solar, mechanical and thermal sources, thereby leading to more efficient self-powered systems.

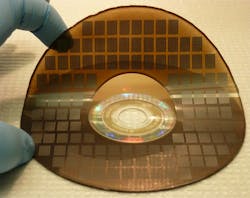

In other technology news comes word from Xerox’s Palo Alto Research Center (PARC) about a new system for making electronics. Based on laser printer technology, this new advance has lead to desktop manufacturing of circuitry for electronic devices. In a report on this technology in The New York Times, the devices these desktop printable chips, often referred to as chiplets due their grain of sand size, could be used for include “flexible smartphones that won’t break when you sit on them; a pressure-sensitive skin for robot hands; and smart-sensing medical bandages that could capture health data and then be thrown away.”

Having received financing from the National Science Foundation and DARPA, Xerox PARC researchers have created a machine similar to a laser printer that can “precisely place tens or even hundreds of thousands of chiplets on a surface in exactly the right location and in the right orientation,” reports The New York Times.

What struck me most about this advance is that these chiplets are reportedly capable of working as both microprocessors and computer memory as well as the other circuits needed to create complete computers. The New York Times also reports that these chiplets can operate as analog devices known as microelectromechanical systems, or MEMS, that perform tasks like sensing heat, pressure or motion.

These two technology advances directly impact two of the most critical areas to modern manufacturing advancement—energy and computing power. Exactly how these technologies will play out in the manufacturing sector remain to be seen. But it’s obvious that both will have a big impact on the industry.

Read more Automation World coverage about how embedded technologies are changing automation.

The video below highlights the development of the graphene supercapacitor.