building a better robot.

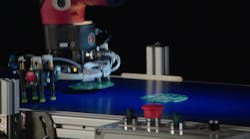

At Rethink Robotics, we believe that all manufacturers, regardless of size and technology experience, should have an equal opportunity to benefit from industrial robots. They should be affordable. They should be safe to operate around people. They should be easy to train and work right out of the box. And most of all, they should help U.S. manufacturers increase production while keeping jobs from migrating overseas.

Rethink Robotics is a new kind of robotics company, and our mission is to create a new kind of manufacturing robot. One that introduces robotics into processes that manufacturers have never been able to cost-effectively automate. One that uses common sense to perform a wide range of tasks and vastly improve productivity. And one that safely works side by side with its human counterparts, who are able to train it with no programming or engineering expertise.

Simply put, we are rethinking robotics. And we think you will, too.