What Does Quartz Have to do with Automation?

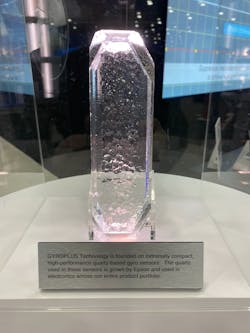

The precision that quartz—a mineral made of silicon and oxygen—brings to watches and clocks has been well known for decades. Outside of timepieces that you wear or clocks integrated into computers and appliances, the frequency precision of quartz is not widely used. Epson Robots, however, sees a key use for it in automation, specifically robotics.

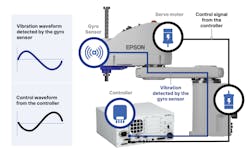

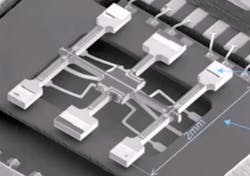

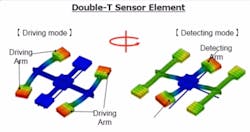

The company uses its quartz to create a gyro sensor that provides a high signal-to-noise ratio, resistance to vibration and shock, and high temperature stability. Epson applies this gyro sensor in its robots to detect and dampen rotational and vertical vibrations, without adding mass to the robot or increasing its size.

According to Epson, its GyroPlus technology enables the development of smaller, lighter-weight robot arms that can “execute faster moves, handle heavier payloads and provide better precision than traditional robots without this technology.”

Controlling robot movement

A key factor in robot control involves the estimation of how the end of the arm is moving and issuing control commands needed to deliver the required position and velocity based on position and speed information from the robot’s motor encoder. Because a robot arm isn’t completely rigid, some amount of vibration or deflection is caused by the robot arm’s movement. This vibration increases across three factors: the distance of the end of the robot arm from the motor, the robot’s speed and the weight of the robot’s payload. As a result, the actual speed and position at the end of the robot arm can differ from the amount estimated based on motor use, leading some vibration aspects at the end of the arm to go undetected by the motor encoder. This can impact the robot’s ability to reach the intended position.

“GyroPlus takes a very small gyro sensor—about the size of the end of a pencil lead—and Epson puts that inside the robot arms to provide a feedback loop on vibration in real time for the motion control algorithms which then compensate for that motion,” said Marsic. “That gives us the ability to reduce that vibration at the end of the robot arm to deliver micron-level precision.”

In terms of what this means for industry, Epson says that applications that once required Cartesian and/or gantry robots for high-speed, high-precision can now use SCARA and 6-axis robots to “achieve the same or better performance, but with a much smaller footprint, less mass, simpler integration and less complex programming.”

In the video below, Scott Marsic of Epson Robots explains the company’s development and use of quartz in its robotic systems.