Beckhoff Highlights Futuristic Materials Handling and Software Updates

Last year, Beckhoff Automation introduced its XPlanar “flying motion” material handling technology in North America during the virtual PACK EXPO Connects event. At this year’s return of PACK EXPO as a live event in Las Vegas, Beckhoff is highlighting updates to its XPlanar system.

According to the company, XPlanar’s capabilities around adaptive packaging, as well as material handling and inspection, allows users to implement non-linear processes and enable true lot-size-1 production. At PACK EXPO, Beckhoff is showcasing how XPlanar’s creates “no contamination through contract-free and wear-free movement” as well as the ability to use any surface covering, such as stainless steel, glass, or plastic, to create a sanitary, washdown-capable XPlanar system in a production or packaging facility.

With speeds up to 2 m/s and max acceleration of 1 g, XPlanar movers can carry payloads ranging from 0.4 kg to 4.2 kg (roughly 10 pounds) and can work together to handle larger payloads. Path planning, automatic collision avoidance, 360- degree rotation, and anti-sloshing functionality are standard in the motor tiles and accompanying TwinCAT software.

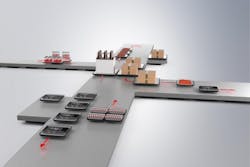

Beckhoff is also highlighting its XTS (eXtended Transport System) linear transport technology—most notably the XTS’s hygienic, stainless-steel version and inherent track-changing capabilities. Recognized for its ability to operate at high speeds and reduce machine footprint requirements while enabling quick changeovers and real-time integration with robotics and other systems, Beckhoff says the IP69K XTS Hygienic “perfectly suits washdown production environments in packaging, pharma, food, beverage and more.”

XTS’s Track Management capability allows users to transfer movers between multiple XTS tracks. Beckhoff says this allows for greater customization, quality inspection, automatic defect ejection, and other critical production and packaging tasks.

Beckhoff is also showcasing new technologies in its TwinCAT 3 software related to integration packages for Internet of Things applications, analytics, robotics, machine vision, and machine learning. For its EtherCAT I/O line, Beckhoff is highlighting new power measurement, overcurrent protection, and TwinSafe functional safety capabilities.