Kawasaki Highlights Packaging and Palletizing Robots

Oct. 26, 2022

2 min read

In addition to highlighting its range of robotics for packaging—from smaller, high-speed robotic applications to more flexible mid-range options—Kawasaki Robotics is also hosting demonstrations with its partners at PACK EXPO International.

For example, Kawasaki and PSA are debuting a “Sniper Cell” equipped with an ultra-high speed Kawasaki Y series delta robot to perform a pick-and-place application using vision sensors and conveyors. Also, with partner IRIS Automation, Kawasaki is unveiling its pre-configured RPZ-MAX palletizing cell which uses Kawasaki R-series robots to handle heavier payloads in a small footprint.

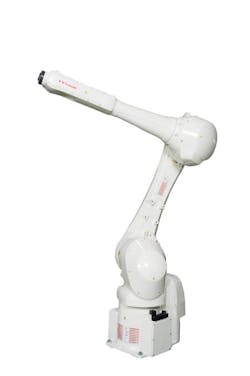

Two new Kawasaki R-series robots featured at Kawasaki’s booth (N-5946) are:

The RS013N, Kawasaki’s newest general purpose robot model with a 13kg payload, 1460mm reach, and IP67 design. This robot features a cantilever design for the upper arm section, enabling a longer maximum reach and an expanded range of motion below, behind, and in the immediate vicinity of the robot.Kawasaki is also featuring its CP180L palletizer robot, capable of 2,050 cycles per hour. This robot has 180kg payload capacity and a 3255mm reach. The CP180L features an energy saving controller and easy-to-use palletizing software for simplified programming.

About the Author

David Greenfield, editor in chief

Editor in Chief

David Greenfield joined Automation World in June 2011. Bringing a wealth of industry knowledge and media experience to his position, David’s contributions can be found in AW’s print and online editions and custom projects. Earlier in his career, David was Editorial Director of Design News at UBM Electronics, and prior to joining UBM, he was Editorial Director of Control Engineering at Reed Business Information, where he also worked on Manufacturing Business Technology as Publisher.

Sign up for our eNewsletters

Get the latest news and updates