Work on OPC UA at the Field Level Advances

Near the end of 2018, the OPC Foundation announced its OPC UA to the field level initiative. The goal of this project, also known as OPC UA FX (OPC UA Field eXchange), is to develop an OPC UA architecture and general model for automated field devices that can easily be adopted by technology suppliers. Once developed, this architecture and general model will be expanded upon with specific, device-type functionalities by specialist working groups.

The OPC Foundation announced updates about the status of OPC UA FX during its 2021 OPC Day International online event. According to Peter Lutz, field level communications director at the OPC Foundation, “We are defining two communication profiles to map the OPC UA information models to the underlying network and transport protocols by supporting a UDP IP protocol as a routable, flexible protocol as well as supporting a direct Layer 2 mapping for highly efficient communication inside a machine, such as for distributed I/Os or high-speed motion control.”

Status of OPC UA FX

The first OPC UA FX specification release has recently been completed and consists of four parts, which are being used to prototype and create test specifications as well as test scripts for the certification tool of the OPC Foundation. Lutz added that these specifications are laying the foundation for two specification enhancements for OPC UA FX—Controller-to-Device (C2D) and Device-to-Device (D2D)—in the next steps of the specification’s development.

Lutz explained that the OPC Foundation is currently preparing a controller-to-controller interoperability demo based on this specification for the next SPS event in Germany this fall. “We expect more than 15 vendors and more than 20 prototypes to be included in this controller-to-controller demonstration, which will show the exchange of process data in real time—even safety data between controllers from different manufacturers,” he said.

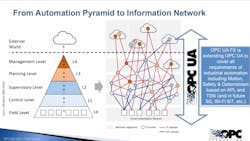

The migration path for OPC UA for future support OPC UA FX was also described by Lutz. The traditional arrangement features OPC UA controllers connecting to edge devices, cloud servers, or MES (manufacturing execution systems) and ERP (enterprise resource planning) systems, with fieldbuses used to connect controllers to the underlying field devices.

“Now, with the controller-to-controller specifications developed for OPC UA FX, we allow horizontal integration communication between controllers of different manufacturers,” said Lutz. “Then by bringing OPC UA down to the field devices using controller-to-device and device-to-device, we [will] then have OPC UA as one consistent and standardized interoperable communication solution that is fully scalable vertically as well as horizontally.”

APL and TSN

The OPC UA FX initiative is also conducting conformance tests of the new architecture with various automation components to ensure compatibility and interoperability with various technology suppliers’ automation devices.

A key technology being focused on here is the Ethernet Advanced Physical Layer (APL) in the process industries, which will help facilitate the use of Ethernet in hazardous/explosive areas.

“Because APL is transport agnostic, it supports different industrial protocols including OPC UA,” said Lutz. “This is why the OPC Foundation became member of the APL initiative—to support further development of the technology and also promote Ethernet APL with other standardization organizations.”

Another key enabling technology for the OPC UA FX initiative is time-sensitive networking (TSN). The importance of TSN was noted during the initiative’s launch is 2018 and Lutz again stressed the reasons for the OPC Foundation’s interest in TSN: 1) the technology’s enablement of deterministic communication over standard Ethernet; and 2) TSN’s supporting for converged networks, where different IT and OT protocols can coexist.

“We are supporting a commonly accepted network infrastructure that is also supported by other OT protocols and their IT stakeholders,” Lutz said of the OPC Foundation’s involvement with IEC/IEEE 60802.