Complex Motion Control with Time-Sensitive Networking

As automated systems involving motion control become more complex, Time-Sensitive Networking enables Ethernet to provide deterministic network communications.

With Time-Sensitive Networking (TSN) now supported by all the major industrial networking protocol organizations and TSN-capable network devices being released, the use of Ethernet for deterministic motion control is ready for application by the manufacturing industries. If you’re unfamiliar with TSN, it’s an IEEE 802.1 vendor-independent standard that allows time-coordinated and regular traffic to coexist on Ethernet while ensuring time-sensitive communications receive priority.

According to Burke, TSN, in addition to offering microsecond-order time synchronization accuracies, can prioritize urgent, time-sensitive traffic as defined by the IEEE 802.1Qbv traffic scheduling profile. “It can also reserve cycle time for the transfer of regular messages, such as control data packets. The capability to block set timeframes for recurring motion signals dramatically reduces latency and jitter, ensuring deterministic performance,” he says.

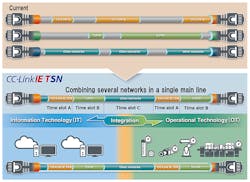

These functionalities of TSN are guaranteed “even when large volumes of less transient types of traffic need to be transmitted over the same network,” says Burke. This means that OEMs no longer need to configure specialized communications infrastructures for motion control, enabling them to simplify network architectures and reduce wiring costs.

Machine vision applications

The capabilities of TSN extend beyond deterministic core motion control applications to support systems using machine vision systems. This requires the merging of motion control traffic with camera data, which generally use TCP/IP. “This can be easily achieved with an innovative network technology that incorporates TSN functions, as these can also drive the convergence of other types of messages, including those from the information technology (IT) domain,” says Burke. “Consequently, it is possible to create highly interconnected factories and enterprises to drive efficiencies and, ultimately, competitiveness.”

Burke adds that CC-Link IE TSN is the first open industrial Ethernet with TSN functions— in addition to gigabit bandwidth—achieving a cycle time of 31.25µs. “This is being used by a large and rapidly growing base of industrial automation vendors within a wide range of drives, controllers, robotic systems and accessory devices,” he says.

About the Author

David Greenfield, editor in chief

Editor in Chief

Leaders relevant to this article: