How Modbus Monitoring Devices Simplify IIoT for Manufacturers

Why this article is worth your time:

- Learn how affordable and straightforward Modbus monitoring devices provide an accessible pathway to leverage IIoT benefits without expensive overhauls.

- Understand how these devices optimize operations, from energy monitoring and predictive maintenance to server room management.

- Get insights on how these devices integrate with legacy networks to enhancing scalability, reliability, and operational efficiency.

For many manufacturers, the Industrial Internet of Things (IIoT) has paved the way to better efficiency, predictive maintenance capabilities and data-driven decision making. Yet across the industry landscape, the realities of implementation have varied significantly.

Whereas major corporations have invested millions of dollars in comprehensive digital transformation efforts, many manufacturers have found it difficult to justify the cost and complexity of traditional IIoT implementations. This is especially true for companies with significant amounts of legacy equipment and associated protocols.

Many of these facilities still use Modbus — a communication standard that serves as the backbone for many critical industrial and control systems due to its simplicity, reliability and open architecture. This has led more companies to explore how they can use Modbus to their advantage to efficiently collect, process and visualize information for IIoT applications without investing in complex, custom solutions or complete system overhauls.

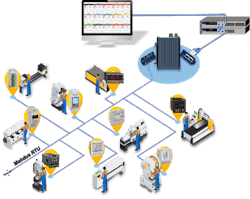

In response, a new architectural approach is emerging that uses self-contained data collection units designed to integrate with both new and legacy Modbus devices. This approach offers a straightforward entry point into the world of IIoT, allowing more organizations, especially small- and medium-sized companies, to begin their digital transformation journey with minimal investment and technical overhead.

The IIoT gateway device

These data collection units, such as Altech’s DO-1, have their own alerting and data storage capabilities, enhancing the device’s functionality as a monitoring solution. When these devices are combined with Modbus, they present a unique opportunity for enterprises of all sizes to begin to take advantage of the IIoT — particularly when it comes to collecting data at the sensor level.

In addition, these Modbus monitoring devices require no special technical skills or IT specialists for installation and operation. They offer the ability to connect a variety of sensors and data-logging devices, allowing users to monitor and analyze various parameters, such as energy consumption, current, voltage, temperature, humidity, motion and noise levels.

Here’s a rundown of the common capabilities of these devices:

Monitoring and alerting. Capable of monitoring up to 128 Modbus RTU/TCP devices, devices like the Altech DO-1 with its web-based software facilitates configuration and supports the creation of custom dashboards to visualize data. They also support individual alert or event settings with email notifications, enabling users to receive real-time alerts about the status of their monitored systems.

Data collection and analysis. These monitoring devices offer robust data collection capabilities that allow users to extract filters for data to Excel or CSV files for analysis and reporting. The device is equipped with a real-time clock with 30-day battery backup, ensuring continuous operation even during power outages.

Connectivity and storage. The Altech DO-1, for example, supports dual power input and offers 5 GB of internal data storage with the option to expand up to 128 GB using an external SD card. It also features a compact design with an optional DIN rail adapter for easy installation. Wi-Fi and Bluetooth connections are supported.

The benefits of Modbus monitoring devices

Developed to help companies monitor their plants and machines in a cost-effective and simple way, these monitoring devices support integration with both new and legacy Modbus networks, taking advantage of the protocol’s widespread use across industries to enable fast, efficient data monitoring.

For small- and medium-sized manufacturers, the benefits include:

Cost-effectiveness. The devices have minimal hardware requirements and no subscription or license fees, making them an economical choice for companies looking to enhance their IIoT capabilities.

Real-time data exchange. Modbus monitoring devices facilitate real-time data exchange, enabling companies to monitor and control processes efficiently, improving operational efficiency and reducing downtime. This means they can also unlock proactive maintenance capabilities, allowing operators to analyze data, set thresholds and identify potential issues before they cause major problems.

Flexibility. Modbus monitoring devices support Modbus RTU and Modbus TCP protocols. This dual support allows for flexible integration into existing networks, whether they are based on serial communication (RS485) or Ethernet. The ability to switch between these protocols enhances the adaptability of Modbus devices in industrial settings.

Robustness and reliability. Designed to operate in harsh industrial environments, Modbus devices can withstand electrical noise, temperature fluctuations and mechanical stress, ensuring consistent performance and maintaining uninterrupted operations in industrial settings.

Scalability. The Modbus protocol supports multiple physical layers and transmission methods, supporting flexible configurations. This scalability ensures Modbus monitoring devices can grow with the expanding demands of industrial operations, accommodating additional devices and increased data loads as needed.

Security considerations. Industries can integrate Modbus devices with secure networks and protocols to mitigate potential security risks, ensuring safe and secure data transmission.

Markus Kraess is product manager at Altech Corp.

More industrial network insights from Automation World:

What is Modbus?

Developed in 1979, Modbus is one of the most widely used protocols in industrial automation. As an open standard with a straightforward message format, it ensures compatibility between devices from different manufacturers while remaining easy to implement and debug. It offers flexibility through support for multiple communication modes (RTU, ASCII, TCP/IP) and physical media (RS-232, RS-485 and Ethernet), and it has proven its reliability over decades of use in harsh industrial environments.

The Modbus protocol's simplicity reduces deployment time and effort, making it cost-effective due to its minimal hardware requirements. Its widespread adoption spans many industries, including industrial automation, building automation, energy management and transportation.

Modbus monitoring devices are suitable for many applications — from industrial automation and process control to smart building and energy management systems. Examples include:

- Liquid level monitoring.

- Building energy monitoring.

- Machine monitoring in factories.

- Remote machine status monitoring and data logging.

- Monitoring warehouse sensors, e.g., light, load, motion and proximity sensors.

- Monitoring sensors in server rooms and data centers.

- Vibration monitoring in rotating devices.

- Airflow monitoring.

- Pressure monitoring.

- Flow monitoring.

About the Author

Markus Kraess

Markus Kraess is product manager at Altech Corp.