How Edge Computing Helps Deliver Reliable Automated Pressure Testing

Engenuity Inc. provides control automation and data integration solutions with a primary focus on advanced technologies for the oil and gas industry. Through their work in this industry, they have identified specific deficiencies in validation pressure testing of blowout preventers (BOPs) and well control equipment. These tests are often executed manually and can cost operators millions of dollars annually.

In collaboration with customers like Shell International Exploration and Production Company, Engenuity developed a set of fully automated test execution and reporting products. Their high-reliability solution uses Opto 22’s groov EPIC (edge programmable industrial controller) to integrate critical functions like process control, text and email notification, and process history storage and replication.

Using Engenuity’s BOPX testing software, system operators can map out valve arrays and their associated pressure limits, then automatically execute and report on a variety of test scenarios. Engenuity’s EZ Valve retrofittable actuator integrates manual gate, low torque, and plug valves into this automated system, actuating up to 70 valves through as many as 30 test sequences. Engenuity’s EZ Vision leak detection sensors add acoustic analysis to the system to help pinpoint the location of leaks.

While Engenuity has added many features to the BOPX system over the years, Ted Royer, a controls engineer with Engenuity, stresses that “all the test software is on the EPIC. BOPX is just an interface now.”

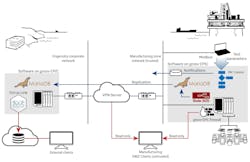

It’s primary role in test execution is to send configuration data to the groov EPIC edge controller over a Modbus/TCP connection using the EPIC’s configurable firewall to protect critical control data. One of the controller’s two network ports is configured as a read-only interface joined to an untrusted network named the Manufacturing Demilitarized Zone (DMZ). The other network port is joined to a separate, trusted network, named the Manufacturing Zone, where all I/O and control communication takes place. The EPIC prevents routing traffic between its two ports, so there is no risk of untrusted connections tampering with configuration, execution, or process history data on the trusted network.

With configuration data securely transmitted, the edge controller begins executing test scenarios. Automated valve manifolds and EZ Valve and EZ Vision connections are integrated directly into the EPIC’s local I/O modules or into additional EPICs used as remote I/O.

As test execution proceeds, the primary controller monitors the process. “We have a really well-developed alarm system we’ve developed over decades,” Royer adds. “It runs in the controller, not the HMI, so it’s available to other systems,” including external mail and messaging services, which the control program contacts to generate notifications for a range of conditions.

The primary controller also stores process data to an internal MariaDB server, a popular and proven open-source database management system. MariaDB is available in a cryptographically signed package from Opto 22’s Linux repository. Using the free secure shell (SSH) license for groov EPIC, Engenuity can download and install this and many other applications for execution directly on their edge controller. Signed applications prevent the introduction of malware posing as legitimate software.

To transfer data from the control engine to the database, Engenuity uses Node-Red, an open-source IoT engine originally designed by IBM, which is pre-installed and integrated into groov EPIC’s management layer. It provides thousands of functions for connecting and processing data from different sources, including devices, databases, and web services. Engenuity configures Node-Red to monitor I/O, process variables, and events, then transmit these data points to the internal MariaDB server.

Because testing data is used to validate the safety and efficacy of the user’s system, customers need frequent access to process history and often require additional protections to ensure data integrity.

“Typically, on an oil rig, customers just have a Wi-Fi connection to the equipment, which isn’t super reliable,” Royer explains. “Sometimes they want to pull massive amounts of records, even entire jobs, into an Excel spreadsheet. It doesn’t have to be real-time, though, so we will set up another controller here in the office that serves as a replica for the one that’s in the field.”

Instead of burdening the primary EPIC with large data requests, customers connect to the replica controller, which periodically requests updates from the primary MariaDB server. “We have plenty of bandwidth here [in the office],” adds Royer, “so it gives them the best of both worlds.”

To facilitate secure data exchange, Engenuity joins the replica controller to the off-shore Manufacturing Zone network over a point-to-point VPN connection. Engenuity then grants customers read-only credentials to this private network. Engenuity houses multiple replica controllers in their offices, each of which connects to the outside through a separate, dedicated VPN appliance. “It’s simple and as bulletproof as we could make it,” says Royer.

If a customer wants to distribute process data beyond a single site, Engenuity takes advantage of the embedded Ignition Edge platform on groov EPIC. Designed by Inductive Automation, the platform’s modular architecture allows Engenuity to install a range of components, including functions to send OPC tag data directly to cloud services like AWS, Azure, Google Cloud, or IBM Cloud. Once there, customers can access testing data around the world.

For Engenuity’s customers, the cost of downtime may be $15,000-$20,000 per hour, so BOPX must execute quickly and reliably to deliver value. Engenuity decided to standardize on EPICs over traditional PLCs because the integrated automation lowered the cost of operation and maintenance while helping them deliver a more competitive solution.

Depending on an installation’s size and operations, Engenuity’s BOPX testing system can save 10-20 hours for each full test with a fully integrated system. With high uptime and automated testing, Engenuity’s customers can reduce on-site staff and have adapted more easily to remote operations.

“There are so many advantages to having a full control system that can tell you what’s wrong,” says Royer. “I’ll get a text [from the control system] in the middle of the night, and I’m already logged in by the time [the customer] calls me. I can tell them exactly where the problem is, and usually, it’s something simple.”

With traditional PLCs, Royer also points out, Engenuity’s solution would require ongoing support from IT, but with edge controllers, they are able to manage the entire solution themselves.

“[Users] don’t have space for racks of servers. These [IT rooms] are non-classified areas in the middle of hazardous areas. They are designed to be half full and [typically] they are overfull. So now you are going to replace that with stuff that can go outside in a NEMA 4 box…[Our EPIC’s] got 9 servers on it and we haven’t even taken up 1 foot of space! If you want another one, it’s only another $1500.”

With edge control, Engenuity eliminates complex multiproduct integration requirements and delivers seamless operation and instant data access. Jeff Hilpert, president at Engenuity, adds, “The integration of data and control on a single backplane has been key to dramatically lowering cost, improving uptime, accessing data, and expanding utilization.”

To learn more about Engenuity, find them at engenuityinc.com.