Today’s top manufacturers, particularly the upstream oil and gas companies, got to where they are today by leveraging data and business analytics to get ahead of competitors. So how quickly can your company visualize and access the information it needs?

One of the primary challenges most companies face is the long development cycles required to grow a system due to the significant work typically required to add new equipment to existing SCADA systems. For example, when you add a new line or, in the case of the oil and gas industry—a new well, adding its information to your systems is crucial to address any malfunctions. But this means adding a new screen that requires extensive customization and testing.

These development delays can interfere with your company's ability to respond to market changes. The slow pace of adaptation isn’t just a threat to the financial and operational security of your company; it challenges the basic safety of your operators. Development cycle delays leave operators with less information and make it harder for them to prioritize and address safety concerns.

Recognizing this need for a more streamlined approach to SCADA system development, CSE ICON developed the Upstream Accelerator for Ignition—a framework with customizable templates that slash the time you need to bring new equipment online.

Advanced development with visual limitations SCADA (supervisory control and data acquisition) systems were developed in the 1960s. Due to their long lifecycle, it’s not uncommon to come across a SCADA system that has been in operation for decades.

The cost and risk of replacing or updating the system to make it more visually pleasing raise concerns that range from security, because of potential new vulnerabilities, to financial loss caused by expensive downtime. This is why many SCADA visualizations are similar to that shown in Figure 1.

Ignition, an industrial applications platform for building SCADA systems, is widely recognized for three main things:

- Application customization: For any operational needs, you add or modify modules.

- Flexibility across platforms (and environments): Operating on Windows, Linux and macOS.

- Scalability and integration: Single or multiple servers and unlimited tags.

A framework to reduce development time, CSE ICON developed the Upstream Accelerator for Ignition in the Ignition Perspective platform (from Inductive Automation) to combine the strength of Ignition’s robust development with modern visualization capabilities (Figure 2).

The idea of the Upstream Accelerator application came from a simulation software CSE ICON wrote for an older Ignition demo. A couple of clients started using it (and continue to use it), and CSE ICON keeps providing support while enhancing the application with new features.

This tool acts as a framework for HMI screens catered to upstream oil and gas customers, who often need a more standardized process. You could describe it as an accelerator package to kickstart the implementation of customized dashboards and screens.

One of its more prevalent features is having different profiles for the resources involved in a specific process. For example, an operator responsible for monitoring alarms on equipment will have a profile that displays only the relevant dashboard. This dashboard uses customized widgets tailored to their tasks (see Figure 3).

This focused approach not only keeps personnel on task but also speeds up their access to necessary information, eliminating the need to navigate through multiple screens.

The Notes feature in the Upstream Accelerator for Ignition feature is designed to keep teams across different shifts updated on recent incidents, alarms and other important events that impact day-to-day operations.

As you can see in Figure 4, there are options for users to easily filter information by specific facilities or types of equipment.

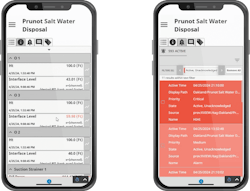

Working in the field means desktop access isn't always possible. The mobile view feature of the Upstream Accelerator eliminates the need for desktop access to the SCADA system. It lets you use your smartphone to quickly check the current status of your equipment. Figure 5 shows the mobile view.

Key user benefits

Following are some of the benefits the Upstream Accelerator can provide to users in the oil and gas industry:

- Contextualized design: The layout and functionalities align closely with real-world operations. This contextualization enhances user familiarity and usability.

- HMI framework: The incorporation of a high-performance HMI framework ensures that the layout and flow of information follow intuitive patterns, such as left-to-right and top-to-bottom, maximizing user comprehension and efficiency.

- Metadata-driven configuration: This allows for dynamic screen generation based on various equipment types and locations and reduces the need for manual programming to streamline the process of adapting the tool to different scenarios.

- Customizability and scalability: Users can make enhancements and additions independently, reducing dependency on external support and enabling scalability.

We’ve seen that the Upstream Accelerator can reduce development time by three to six months, which not only offers operational efficiency but also reduces costs associated with prolonged development cycles.

CSE ICON designed the Upstream Accelerator for Ignition to modernize SCADA systems, with the aim of making the interfaces as intuitive and visually appealing as modern mobile apps. This effort reflects a commitment to improving user experience and aligning industrial software with the sleek, user-friendly design of today’s technology.

Andrew Martin is SCADA and control engineer at CSE ICON, a certified member of the Control System Integrators Association (CSIA). For more information about CSE Icon, visit its profile on the CSIA Industrial Automation Exchange.

About the Author

Leaders relevant to this article: