Vibration sensors monitor the performance of motors, pumps, and other rotating assets such as fans, compressors and gearboxes to catch maintenance issues before they cause machine failure resulting in unplanned downtime and possibly secondary damage to attached assets. When you analyze the time series of data, even from a single vibration sensor, you can learn a lot of interesting things about your equipment status and performance.

Following are explanations of how vibration sensors can be used to monitor machine states and workloads, identify stresses on your equipment assets, and deliver notices of cavitation and lubrication issues.

Machine states

Do you know when a given machine is running routinely and for how long it stops? This information can help you improve machine scheduling by better understanding the demands placed upon it.

Machine workload status—low, medium, high—can be assessed with a single vibration sensor. In turn, this information can help you determine where new equipment might be needed now—or will be needed in the future—based on current usage trends.

Asset stress

By revealing misalignment of a motor and other components, you can understand the stresses put on the assets, allowing you to properly align the equipment before the issue leads to premature equipment degradation or unexpected failure and downtime. Following are four common causes of rotating asset failure:

1. Misalignment of the motor to the pump—To transmit power from a motor to a pump, the motor shaft is connected to the pump shaft. If these shafts are not properly aligned, it can cause early wear on the shafts, coupling or pump seal, as well as cause early bearing defects. Each of these can lead to reduced pump life. There are two ways a motor and pump can be misaligned: parallel and angular. In a parallel misalignment, the centerlines of the motor and pump shafts are parallel but not lined up. In an angular misalignment, the motor and pump shafts are at an angle to one another. Misalignment typically results in noise, vibration and eventually fluid leaks and it also reduces system efficiency. Problems with motor-to-pump misalignment can be detected by analyzing velocity and bearing temperatures.

- Bearings will exhibit a high-frequency vibration, not audible to the human ear but detectable with vibration sensors.

- The bearing vibration will generate a frequency spectrum composed of bearing cage vibration and “false spin” vibration. It is at this and subsequent stages that typical vibration sensors can detect the onset of bearing problems.

- Deformities will appear on the outer and inner bearing races, which will cause another level of vibration that generates a telltale band of frequencies.

- Vibration may become audible, in a high pitch, and bearing temperature begins to increase.

3. Misalignment of pump input or output pipe—Pump input and output pipes have flanges to bolt onto mating pipes. If these flanges don’t mate up exactly, it can put a strain on the pipes causing stress that results in vibration. When mating pipes are not lined up perfectly, pipe stress will twist the pump. Vibration generated from pipe misalignment has a unique frequency signature that is used to identify the problem. The results of pipe stress are early coupling and bearing wear.

4. Pump cavitation—Cavitation refers to air cavities or bubbles that rapidly form and burst in a fluid near the pump impeller. These air cavities are often formed when a pump is oversized for the job, causing a higher-than-normal pressure. When there isn’t enough fluid for an oversized pump to pull from, it can pull in air along with the fluid, causing the problem. When these bubbles experience higher pressure, they collapse, producing tiny shockwaves that cause gradual but significant pitting and wear of the impeller, pump housing, bearings and seals.

Sensor notifications

Vibration patterns caused by the formation and bursting of air cavities gradually degrades pump components. The ability to accurately sense this issue allows facilities to service the components to stop the problem before it leads to unplanned downtime and productivity loss

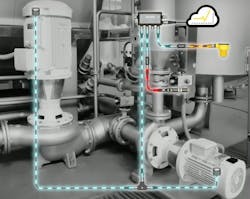

In addition, under, over or fouled lubrication leads to bearing degradation that jeopardizes the asset and attached assets. A single vibration sensor used with condition monitoring software can detect inaudible vibrations, identify them as lubrication problems and warn facility managers via Banner Cloud Data Services (CDS)—a web-based platform that allows users to access, store, protect and export critical data collected by wired and wireless sensors. CDS has analytics and visualization tools that deliver insights and alerts to help solve factory floor challenges.

Banner Engineering offers more than 10,000 products and solutions, including award-winning sensors, wireless solutions, machine safety, indication and LED lighting.