Expert Advice on Making the Digital Transformation

Automation World has been privileged to have an inside track on the work being done at the Georgia Institute of Technology around the digital transformation of industry. Last year we had the opportunity to take part in a roundtable discussion with Georgia Tech engineering, science, and research experts about the trajectories and effects of artificial intelligence and machine learning, and how the intersection of data and technology is changing industry.

Now we’ve learned about new research from Georgia Tech’s Center for the Development and Application of Internet of Things Technologies (CDAIT). This report explores key digital transformation challenges around IoT implementation and scale and suggests frameworks for improving the approach to and efficacy of these programs and their technology elements.

The advice provided in the report can be particularly helpful considering that, despite the critical importance of managing digital transformation, few organizations are using a formal and structured process to approach it. And even fewer companies are managing it strategically and holistically under the direct supervision of the CEO. Research on CDAIT members has shown that only 7.7% of respondents in a 2018 survey identify the CEO as the person in charge of digital transformation.

CDAIT contends that the success of digital transformation initiatives relies not only on the involvement of company leadership but requires constant direction and communication from these leaders to keep the transformation on track. According to CDAIT, a successful digital transformation must:

- Establish enterprise strategic context. Define the why, what, and how at the leadership level to focus initiatives and efforts and communicate it fully and regularly to continually reinforce the company’s strategic north star;

- Take a holistic view of the transformation across people, process, environment, and technology to identify what is in place and what is needed now and in the future for digital success;

- Stay focused on both digital and leadership capabilities. Don’t fall into the trap of overemphasis on technology change—equally important are aspects of culture, change management, and adoption;

- Allow for flexibility and change. Measure progress, make adjustments, and accept that transformation is often an evolution, rather than revolution; and

- Build the organizational infrastructure to support sustained transformation and change because digital transformation is not a one-and-done activity.

Framework Guidance

In an interview following publication of the report, Alain Louchez, co-founder and managing director of CDAIT, emphasized that the digital transformation guidance provided by CDAIT centers on its DIGIT (Discover, Identify, Govern, Implement, Track) framework—five stages of digital transformation programs that "must be perpetually and iteratively managed through a front-end strategy/planning process and a back-end delivery/management process. Our DIGIT framework abstracts what is an inherently unique and often complex and messy transformation process into a simpler form, allowing us to reveal those actions and activities we believe are mission-critical for digital business transformation and, therefore, IoT program success."

Louchez noted that the findings in the report were derived with the input of several CDAIT company members—an effort spearheaded by Michelle Mindala-Freeman, chair of the CDAIT IoT Thought Leadership working group, and Sébastien Lafon, vice chair of the CDAIT IoT Standards and Management working group.

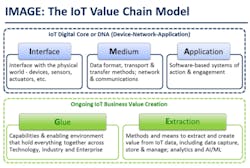

Though CDAIT correctly contends that a digital transformation is not just about technology, the report directly address a number of technology-specific issues. These technology aspects are addressed in CDAIT’s IMAGE (Interface, Medium, Application, Glue, Extraction) model. This model describes the end-to-end framework and key components of the Internet of Things value chain, which is, according to CDAIT, “composed of many moving parts—not just technology, but also the enabling environments, data created, and the platforms and processes needed to extract value from connected things.”

The report stresses that making the digital transformation an exclusively technological endeavor “not only misses the point, but is downright risky if not dangerous for the firm across multiple dimensions…technical, financial, operational, cultural, and managerial…and even risks company brand and reputation. Therefore, the tools provided in the IMAGE model, the DIGIT framework, and our recommendations are designed to augment traditional project delivery and management practices by addressing both the ‘what’ (i.e., what is important, what must be addressed) and the ‘why’ (i.e., why are we doing this, why should we continue).”

Technology Glue

CDAIT’s IMAGE model addresses the digital transformation’s technology “glue” via interoperability and integration, security, standards, platforms, and power management.

CDAIT says that, even though initial instantiations of enterprise IoT solutions will not be infinitely complex, it is “folly to leave testing for quality and performance to chance.” Therefore, it recommends IoT leaders make creating models, executing simulations, and performing experimental runs a prerequisite for launch and to include staged versions of modeling and simulation in their programs’ agile/iterative development and release process.

Speaking of modeling and simulation, the factors CDAIT highlights as requiring attention as IoT projects mature and expand are: scalability of simulation fabric, elastically modeling sensor populations, modeling device heterogeneity, modeling heterogeneous data models and extraction methods along with specific regulatory and safety tests, holistic performance evaluation, and security vulnerability testing.

“While it makes technological sense to walk before running—that is, to model and simulate before deploying—it must also make financial sense,” the report states. “Akin to insurance, modeling and simulation looks expensive before adversity strikes. But, IoT-focused businesses must understand that embracing modeling and simulation in project development and management is good practice and will help avoid unnecessary costs to address issues later.”

Power management as it relates to digital transformation projects is not often addressed in IoT planning, but CDAIT includes it prominently in its report. “With massive device connectivity in the future, it will be impractical and inconvenient to connect all devices to perpetual power sources or too expensive to regularly re-charge or replace power sources over time,” CDAIT says.

To address this, CDAIT suggests power management considerations should include “exploration and use of new sources of power, especially in the area of energy harvesting or scavenging. Energy harvesting refers to the process whereby power-generating elements are incorporated into electronic systems. These might include solar cells, piezoelectric elements or thermoelectric elements. Beyond harvesting, there is ongoing research and development in other power management areas, such as supercapacitors, wake up receivers, on-chip batteries and nano-generators, all of which can help improve power access, storage and efficient power use.”

IoT Platforms

A major consideration of manufacturing firms when it comes to digital transformation is the role of platforms. Every major automation supplier centers its digital products around its platform, even if the platform and related products can be used with third-party platforms and products. This can make the platform decision-making process a difficult one for end users to navigate.

As CDAIT notes, “the explosion in the number of IoT devices has led to a proliferation of platforms. One 2019 list showed 400 companies with IoT platform capabilities. The IoT research firm, IoT Analytics, distinguishes five different platform types: cloud platforms, application enablement platforms, device management platforms, connectivity platforms and advanced analytics platforms. Each of these may be deployed in different ways (from on-premise to cloud) with different licensing and usage models.”

Because the role of platforms in the IoT value chain is to “provide the environment where devices can connect; data can be stored and retrieved; applications can leverage platform services and integration; and extensibility can be provided to various IoT solution components, business processes, and workflows,” CDAIT says the determination of what platform to use “is a key choice to make early on, since changing platforms when the business is scaling is a really hard problem. Tradeoffs to be considered while making choices include cost, the software stack, applicability to the business problem being solved, support, and skillset.”

About the Author

David Greenfield, editor in chief

Editor in Chief

Leaders relevant to this article: