OEMs Can Succeed No Matter the Economic Situation

OEMs have always faced the prospect of world economic uncertainty impacting their ability to pivot to the new—the lifeblood of success in the OEM market. But today, as volatile market dynamics increase and companies experience more industry disruption, they may want to adopt a new approach that can help them prevail against uncertainty.

The age of disruption is already hitting OEMs, and its impact is expected to further strengthen in the coming years. Companies are increasingly embracing the mantra to ideate and innovate more to compete—especially against new-market entrants trying to conquer the customer interfaces of the established players. According to our research, key, global OEMs—as well as automotive, high-tech, consumer goods and services, and retail players—remain vulnerable to ongoing disruption.In addition, some of the largest OEM markets tend to show serious signs of slowing momentum. For example, the percentage of change in gross domestic product growth from the second to third quarter of 2019 showed a negative change of 8% involving major markets, such as the U.S., Japan, and Germany. Moreover, this trend is impacting revenue growth and profitability of OEMs in multiple industries.

This is not to suggest that a recession is on the way. But it does mean that between economic uncertainty, disruption, fluctuating customer demand, and potential tough times, the findings underscore the importance of continually adjusting the business to the state of economic conditions while striving for success and competitive positioning. Also, to prevail against declining growth, organizations should adopt flexible cost structures, cost-saving technologies like artificial intelligence, and aggressively pursue more market share.

In addition to aligning appropriate investment intensity to your company’s current situation, there are three strategic levers an OEM should use to balance and pivot wisely to the new:

1. Transform the core business by aggressively digitizing where possible;

2. Grow the core business with the help of intelligent data-driven products and services; and

3. Scale the new business based on the intelligent enterprise and a service and outcome portfolio.

The mix between these three levers will need to be adjusted to the specific business and market conditions in which the OEM operates. Consider these scenarios:

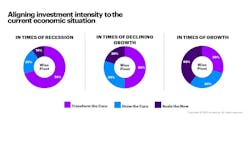

• In Times of Recession, OEMs may consider investing at least 80% of resources in the core business to extract its full value. This includes implementing critical activities, such as strategic cost reduction and zero-based budgeting initiatives, and using digital applications to reduce cost, while enhancing core capabilities. Also, OEMs may consider investing the remaining 20% in the new. One multinational conglomerate, for example, transformed its core by reducing the number of its divisions and manufacturing facilities. This helped them deploy a global enterprise resource planning system that reduced cost and increased workforce efficiency.

• In Times of Declining Growth, increase transformation investments, keep growth investment intensity, and adjust investment in the new in line with the current situation. Actions taken to sustain growth may include reinventing the core as a living business, monetizing underutilized assets, and building strategic partnerships. A major tire manufacturer and leader in sustainable mobility grew its core by expanding its specialty tire business and establishing a tire joint venture that helped them become the second largest tire wholesaler in the U.S.

• In Times of Growth, while there will be less pressure during this period, it will remain important to maintain an equal balance between all three investment areas. This will help companies protect the progress made and give them the ability to scale the new to drive future competitive agility.

Successful industrial equipment companies will be the ones that are able to move up and down swiftly between these three levers in an ever-changing world economy.