Growing New Business with Edge Computing

As industrial edge devices become more common for building connected systems in the Industrial Internet of Things (IIoT) and automation, they are creating new business opportunities for system integrators and manufacturers. By simplifying the traditional architectures required to connect field assets to software systems, edge devices make many applications more affordable and practical.

Let’s look at a couple of real-world examples.

Equipment-as-a-service (EaaS) involves renting out or providing access to equipment and collecting payment periodically, rather than selling the equipment outright. This payment model enables end users to pay for costly or infrequently used equipment as an ongoing operating expense, which can open new markets for machine builders.

Martins Electrical Service, a Pennsylvania-based system integrator, was hired to design a new EaaS option for an automated truck wash system. Shumaker Industries, the manufacturer of the wash system, wanted to add a remote monitoring option for customers interested in a rent-to-own arrangement. However, the programmable logic controller (PLC) they used didn’t have the ability to perform the database transactions needed to record monitor usage.

Initially, Martins experimented with a proprietary remote monitoring system—wireless sensors that pumped data into a cloud database through a local IoT gateway. The problem with this system was that it could only deliver updates every 10 minutes and the data was locked in the vendor’s private storage system.

Then Martins heard about Opto 22’s groov RIO edge I/O module and decided to tranther approach.

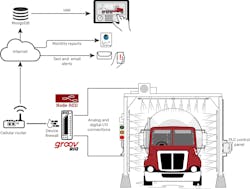

Rather than installing additional sensors, Martins used groov RIO’s 10 software-configurable I/O channels to capture existing sensor data in parallel with the wash system’s PLC. Using Node-Red—IBM’s open-source IoT platform embedded in groov RIO—they organized the I/O data into timestamped sets associated with a vehicle number. They then connected a 4G cellular router to the groov RIO module and pushed the data structures into cloud-hosted storage rented from MongoDB.

This arrangement allowed them to deliver a scalable monitoring system without worrying about vendor lock-in or IT infrastructure maintenance. And by simply grabbing existing I/O signals, they avoided the need to communicate with or modify the manufacturer’s existing PLC controls.

To complete their EaaS design, Martins built a web-based dashboard that let Shumaker visualize the wash system in operation with one-second resolution. The system also generates email and text alerts in Node-Red, including a monthly report on the number of trucks processed by each system, which Shumaker uses to calculate billing.

“Since it’s an edge device, with security built in, groov RIO is perfect,” says Leslie Martin, an automation technician at Martins. “It’s a small add-on, so it’s easy to make an option for customers.”

From concrete to enterpriseWith nothing but investor money and an empty denim processing plant, Emerald 66’s goal was to go as fast as possible. The company understood they were competing against low-paid, high-volume workforces operating manually and believed they could use technology to do more with a smaller, better-paid workforce.

The quickest way for Emerald 66 to build a new packaging process was by acquiring a variety of equipment at auction, leaving NACI the task of integrating it into a cohesive system.

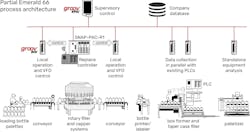

NACI decided to make Opto 22’s groov products the focus of their strategy, so they could capitalize on the flexibility offered by edge devices. They used groov EPIC edge programmable industrial controllers to supervise the process lines, control equipment not already managed by a control system, and manage database transactions.

In addition, NACI used groov RIO edge I/O modules as a rapidly deployed remote I/O solution. As each new piece of equipment came online, NACI dropped in a power-over-Ethernet groov RIO module and used its software-configurable channels to identify the kinds of signals the unit provided. Next, the module was used to mirror the I/O signals in parallel with any existing PLCs and to integrate that data into the groov EPIC control system.

This integration required no modifications to the control systems already in place, allowing NACI to move very quickly. In three months, they had 15 pieces of equipment up and running.

From here, automation of applications grew from processing a high volume of one-gallon, single-formulation containers to working with a variety of sanitizer chemistries in different batch sizes and packaging form factors—from small two-, four-, six-, and eight-ounce containers, hand pumps, and spray bottles, to large jugs in excess of one gallon.

Fortunately, NACI’s decision to use a loosely coupled process line made it easy to modify individual segments without interrupting data collection and integration. In combination with on-site panel building and 3D printing capabilities, NACI’s investment in edge-oriented automation allowed them to retool very quickly. Emerald 66 was able to break even on their initial investment within six months.

As Emerald 66 continues to diversify its business, it has also found a valuable niche in original equipment development for overseas export. In one example, using groov EPIC and RIO, NACI took an inline mixer design from concept to implementation in about five days, including a mobile operator interface they built using the EPIC’s embedded groov View HMI server. By their estimate, they implemented the controls in about four hours for a system Emerald 66 will sell for $50,000.

“The fluidity and dynamics of modern manufacturing requires extremely fast response to changing market demands,” says Tom Coombs, principal engineer at NACI. “With groov EPIC and groov RIO, Opto 22 puts dynamic manufacturing data at the edge of the production line and into enterprise systems simultaneously in real-time.”

The key to rapid automation development in both of these cases stems from the flexibility provided by industrial edge devices. With embedded general-purpose computing, networking, and storage, edge devices are able to assimilate automation functions traditionally requiring multiple devices and more complex configuration.

Martins used groov RIO to process I/O data, open a secure connection with cloud services, execute database transactions, and generate reports. In an Industry 3.0 technology stack, all of this would typically require a local PC running multiple applications, meaning more complex and costly security, licensing, and maintenance procedures.

NACI used groov RIO and EPIC in combination to address a variety of integration needs while simultaneously building central data collection and process improvement capabilities. Because each component of the system is capable of handling sensing, control, data processing, and database transactions, the system could be expanded and reconfigured dynamically to keep up with the pace of change.

Given the economic pressures and increased pace of tech adoption that continue even as the world slowly exits the pandemic era, it is likely that designers will look more frequently to edge computing in search of this kind of competitive advantage.