The Internet of Things and the Future of the Energy Industries

Gas networks will continue to grow in both size and complexity. Cross-continental pipelines will increase the global transfer of energy, as well as the complexity of metering, monitoring and control systems. In parallel with the developed world’s reinvestment in smart oil, the growth of the modular oil field has grown and shows no signs of slowing down.

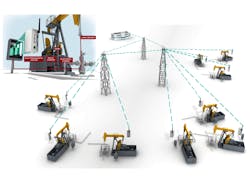

These satellite oil and gas networks compliment large-scale upstream and midstream systems by supporting remote extraction operations. Such oil sites were once considered too remote and small to justify capital investment, but wireless and fiber Ethernet technologies are changing that. Here’s how.

The future of oil and energy control will drive the development of vertically networked integration technologies—bringing oil and gas, electrical grid systems and alternative energy networks together. In oil and gas, this is called “anchoring” and implies that greenfield projects will be physically anchored to existing midstream and downstream infrastructures, such as a pipeline system and processing facility. This allows small to mid-sized upstream sites to become operational more rapidly and supply demand centers while requiring less infrastructure investment. This non-conventional approach is quickly becoming more common as oil prices fall, extraction points grow scarce and less concentrated, and Ethernet and wireless systems grow more capable of connecting the serial world to the Internet of Things.

Why satellite expansion?

It’s cheaper, safer and easy. The practice of upstream satellite expansion owes its success and rapid growth to the industrialized world’s use of wireless networking and remote management technologies. The open standardization of the digital age has allowed a group of key industrial networking manufacturers to enable the oil and gas industry to economically and incrementally expand their flow supply with the Ex-certified wireless and cellular networking technology, greatly improving the pace with which new oil and gas resources can be incorporated into existing flow throughput.

A new generation of smaller and modular digital systems provides localized networks with optimized latent capacity for more efficient control of remote upstream and midstream applications—such as pipeline and processing plant compression, offshore applications and power generation for remote wellhead sites.

For example, an international oil and gas conglomerate that Moxa works with operates thousands of wellheads in high-density zones, but lacks the return on investment (ROI) justification to pull less-dense oil resource zones together to existing pipeline infrastructures. Using serial-to-wireless conversion technologies for both cellular and Wi-Fi, this company can now manage and operate numerous wellheads spread kilometers apart from one another with far less infrastructure and procurement cost. Furthermore, this conversion to open-standard wireless technology allows for future mobile scalability and satellite expansion.

Satellite expansion from existing upstream and midstream oil and gas infrastructure does, of course, create new concerns around security. However, increased interconnectivity and availability offers more opportunity for network redundancy, monitoring and safety innovation because distributed networks are more flexible, functionally autonomous and securable.

A remote monitoring and control network based on industrial Ethernet and wireless is required to remotely manage and immediately access data from wellhead RTUs at the SCADA host. Deep-packet inspection firewall technology can secure sprawling satellite oil and gas networks from operational and malicious cyber attacks. And if the use of wireless communication is not acceptable, fiber-optic cable can be used for secure and long-distance transmission to the field monitoring site to deliver high-bandwidth communication that is equally securable, thereby bringing remote sites together with hubs, while connecting oil and gas to the energy grid.

Oil is just energy, after all

While the mass deployment of wireless and HSE (High Speed Ethernet) in oil and gas is doing wonders for petroleum production, smart city test beds from Southern California to Singapore are evaluating how to better coordinate intelligent traffic systems, energy distribution and storage—not just for altruistic motivations like clean energy, but for economic development and profit as well.

For example, CleanTech San Diego is leading an initiative with UC San Diego, Sempra Energy and other private-sector energy and technology companies to find new ways to identify and capitalize on power inefficiencies throughout the city infrastructure.

The Smart City San Diego initiative is another example of how the world of industrial networking is part of the growing nervous system of the Industrial Internet of Things. Cost-effective industrial wireless and HSE has allowed intelligent sensor devices to move beyond islands of localized operational data and become nodes that deliver and react to real-time, Cloud-based control systems. With such devices, production rates of petroleum can be coordinated and correlated with enterprise-wide power consumption rates, international oil prices, and offshore freighter traffic control networks in real time.

The practice of satellite expansion within the oil and gas vertical is looking more and more like it’s just the beginning of heavy industry’s introduction to the Internet. The practice of implementing sub-netted industrial wireless and HSE networks in smart city control infrastructures, mass transit and power grid systems has put these once very separate verticals on a path to where true interoperability and visibility can be achieved. As a result, the nervous systems of heavy industry are moving away from the slow, expensive and archaic fieldbus structures of the past and toward the infinite possibilities of the Internet’s future.