Though cloud computing will continue to play a pivotal role in Industrial Internet of Things (IIoT) analytics, it’s becoming clear that edge computing will be doing the heavy lifting for plant floor intelligence applications while cloud computing will likely be reserved for longer term strategic planning applications for the enterprise. Evidence for this can be seen in new products with embedded edge computing capabilities and changing business models for OEMs.

Read about the difference between edge and fog computing.

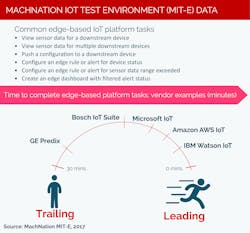

Considering the fast rising importance of edge computing for industry, MachNation—an insight services firm focused on IoT middleware, platforms, applications and services—has created a test environment in which it can test IoT edge-based platforms. As a result, “we have lots of data about the edge capabilities of edge-based platforms,” said MachNation Co-founder and President Steve Hilton.

Hilton pointed out that MachNation’s research into edge computing has revealed five key features that are critical for the technology’s use in industrial applications. Those features are: protocol support for data ingestion, robust offline functionality, cloud-based orchestration, hardware-agnostic scalable architecture, and comprehensive analytics and visualization tools.

Protocol support for data ingestion

“The list of protocols for industrial edge platforms generally includes brownfield deployment staples such as OPC UA and Modbus,” said Hilton, “as well as more current ones such as ZeroMQ, Zigbee, BLE and Thread. Equally as important, the platform must be modular in its support for protocols, allowing for customization of existing communications and development of new means of communicating with connected assets.”

Hilton added that leading edge computing vendors also provide encryption, authentication and data protection functionality. “Retrofitting brownfield deployments to secure machine data at the source is a capability exclusive to leading IoT edge platforms,” he said.

Robust capability for offline functionality

Offline capabilities of an edge computing platform should address three functional areas: data storage with normalization; event processing using rules and machine learning algorithms; and a set of edge-based integrations with local enterprise systems.

Hilton explained that edge systems need to offer two types of data normalization and storage: 1) the ability to successfully clean noisy sensor data, and 2) support intermittent, unreliable or limited connectivity between the edge and the cloud.

As for a flexible event processing engine, Hilton said the importance of this functionality relates to the edge computing platform’s ability to generate insight from machine data. “By analyzing this data with machine learning tools, enterprises can identify behaviors that are valuable to [applications such as] predictive maintenance and cybersecurity. In addition, by applying a set of rules to this data, enterprises can automatically send fault alerts to identify troubles in real-time,” he said.

The integration with local enterprise systems Hilton referred to includes ERP, MES, inventory management and supply chain management systems. “A leading IoT edge platform will provide edge-based integration with these types of existing operational systems to help ensure business continuity and access to real-time machine data,” he said.

Cloud-based orchestration capabilities

Though edge computing is where most industrial analytics will likely occur, cloud computing will still play an integral role in terms in enterprise-level analytics, thus the need for your edge platform to have cloud-based orchestration capabilities. Such orchestration capabilities provide a centralized set of management and oversight functions supporting connected devices.

“An often overlooked yet critical aspect of distributed IoT platforms is their ability to manage and orchestrate newly deployed technologies and processes associated with connected devices,” said Hilton. “In order to harness the true value of IoT, an IoT platform has to provide a set of centralized, efficient and scalable tools for orchestrating the edge- and cloud-based requirements of connected assets.”

These tools should address provisioning, monitoring and updating requirements of connected assets. “First, to simplify on-site deployment and add a level of security, a platform should provide factory provisioning capabilities for IoT devices,” said Hilton. “These application programming interface-based interactions allow a device to be preloaded with certificates, keys, edge applications and an initial configuration before it is shipped to the customer. This greatly reduces the amount of on-site work and troubleshooting that will be required to get the device online. Second, once the device is deployed and operational, the platform should monitor the device using a stream of machine and operational data that can be selectively synced with cloud instances. Third, using over-the-air update capabilities, the IoT platform should securely push updates to the edge. This includes updates for edge applications, the platform itself, the gateway OS, device drivers and also updates for devices that are connected to the gateway. This allows virtually all aspects of a device’s lifecycle to be managed centrally and gives the enterprise complete control over a locally, nationally or globally distributed IoT deployment.”

Hardware-agnostic scalable architecture

The preponderance of devices and systems in place at industrial facilities has brought hardware agnosticism to the forefront of many recent automation technology developments—and edge computing is no exception.

“Using containerization technologies and native cross-compilation, leading edge computing platforms offer a hardware-agnostic approach that makes it possible to deploy the same set of functionalities across a varied set of IoT hardware without modifications,” said Hilton. “In addition, visionary platform vendors employ the same software stack at the edge and in the cloud allowing a seamless allocation of resources and ensuring that edge-based operations are not limited by cloud-based tools. Platforms that are capable of shifting resources between the edge and cloud are better suited at meeting anticipated and unexpected application demands. This makes the overall system more scalable by improving resiliency and operational efficiency.”

Comprehensive analytics and visualization tools

“The most valuable element of an IoT solution is the insight it generates for the enterprise, but distilling that insight from copious amounts of machine data is extremely difficult,” said Hilton. To deliver this at the edge, Hilton noted that IoT platforms with leading edge capabilities will offer “an open and modular approach to edge analytics. Out-of-the-box, edge platforms can aggregate data and run common statistical analyses. For capabilities that require specialized analytics, the platforms should make it easy to integrate leading analytics tool sets and use them to supplement or replace built-in functionality. Then, leading IoT platform vendors will enable edge data to be visualized and actioned on a set of mobile-ready customizable and interactive dashboards suitable for different end users. For development of other types of bespoke presentation layers, customers should be able to select their own best-of-breed visualization or application provider.”

About the Author

David Greenfield, editor in chief

Editor in Chief

Leaders relevant to this article: