B&R Integrates ABB Robotics for Machine Builders

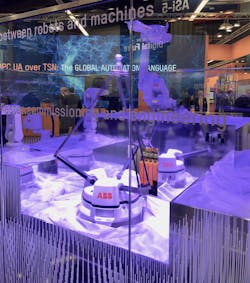

A little over two years since the close of ABB’s acquisition of B&R (which now operates as a unit of ABB’s Robotics and Discrete Automation business), the parent announced that B&R has integrated ABB’s robots into its automation portfolio. Making the announcement at the SPS (Smart Production Solutions) 2019 event in Nuremberg, Germany, the company noted that the principal target of this integration strategy is OEMs, for whom it aims to provide a one-stop shop from which to buy their robots and associated machine controls, I/O, and drive components. Machine builders can now choose a range of ABB robots through B&R, including articulated arm, SCARA, delta, and palletizer robots in various sizes and with various payloads.

B&R says that this merger of robotics and machine control into one architecture is important for machine applications where a high degree of synchronization with other components is required—for example, robotic picking and placing. With ABB robots integrated into the machine automation system, customers will benefit from an unprecedented level of synchronization between robotics and machine control, according to Sami Atiya, president of ABB’s Robotics and Discrete Automation business. Also, since all axes and sensors now communicate on a common network, Atiya says this increases precision to the microsecond range.

Because ABB robots will no longer require a dedicated controller in an integration with B&R automation components, interfaces between the machine and the robot are eliminated. This means that, instead of programming a robotics application in one development environment and a machine application in another, there will only be one application and development environment. B&R’s mapp technology will serve as the platform for developers to set up and configure the machine application, including robotics, without requiring any knowledge of special robotics languages.

Wimmer added that synchronization between sensors and robot motion will also become easier with this integration. For example, the result of a quality inspection with a B&R vision camera can be converted into a control command for the ABB robot in less than a millisecond, so that defective workpieces can be removed from the production process without manual intervention or slowing the manufacturing process.

About the Author

David Greenfield, editor in chief

Editor in Chief

Leaders relevant to this article: