Though the automation scene has been awash in news recently about increasingly successful deployments of Internet of Things (IoT) applications, there have been some equally amazing developments in automation hardware. Just as the IoT holds the potential to dramatically alter the future of manufacturing, I’m equally convinced that a robot that can adapt on-the-fly to a changing environment is an equally important, though more targeted, advance.

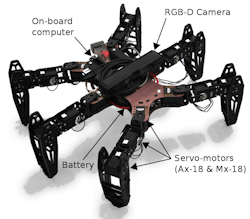

I initially came across this news via a BBC News report detailing how engineers Antoine Cully, Jeff Clune, and Jean-Baptiste Mouret had developed a six-legged robot that was able to re-learn how to walk after having one of it’s legs broken. Of course, self-diagnosing robots are not entirely new. However, as the engineers note in their paper on the subject: “self-diagnosing robots are expensive to manufacture due to the high cost of self-monitoring sensors and are difficult to design because root engineers cannot foresee every possible situation.” Plus, “state-of-the-art learning algorithms are impractical … and even the fastest algorithms constrain the search to a few behaviors.” Lacking these constraints imposed by design parameters, self-diagnosing robots have typically required several hours to successfully respond.

The goal for Cully, Clune, and Mouret is to create a far less costly robot that adapts to challenges as injured animals do to compensate for damage, i.e., by trial and error. Their robot’s adaptive capabilities were developed by “describing the dimension of space of possible behaviors and a performance measure. For instance, walking gaits could be described by how much each leg is involved in the gait (a behavioral measure) and speed (a performance measure). To create [the robot’s] repertoire, an optimization algorithm simultaneously searches for a high-performing solution for each point in the behavioral space.” The engineers note that this step requires “simulating millions of behaviors, but only needs to be performed once per robot design before deployment.”

Of course, there’s much more to this (and you can read it all in their paper), but the bottom line is that Cully, Clune, and Mouret have successfully created a robot capable of learning how to walk effectively with a broken leg in less than two minutes.

Though most applications of such advanced robotics, such as Big Dog are targeted for various military and scientific projects, they are fascinating for the potential they hold for the future of manufacturing.

You can see how quickly the six-legged robot created by Cully, Clune, and Mouret is able to adaptively respond to a broken leg in the video below.

About the Author

David Greenfield, editor in chief

Editor in Chief

Leaders relevant to this article: