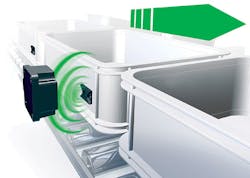

Mount RFID Tags on Metal

This technology allows the RFID tag to be mounted directly on any alloy

or metal surface without the typical interference or loss in range. M-M

tags and heads offer a range of 52mm to 65mm regardless of the alloy

content of the metal, including aluminum, says the vendor. Contained in

a robust, compact housing, the tags are designed to operate in

temperatures ranging from -25°C to 130°C. There are two industrial head

options: a self-contained processor and read/write head with a built-in

RS-232 serial interface; or a read/write head in an identical housing

that can be connected to any of the vendor’s several remote processors.Balluffwww.balluff.com/M-M800.543.8390