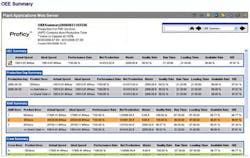

Software Supports Operational Improvement

The software allows manufacturers to make informed decisions about

manufacturing processes and identify ways to drive operational

improvement. It provides visibility into factors such as equipment

downtime, changeover effectiveness, waste and line efficiency, and

supports root-cause analysis by automatically linking downtime events

to a specific causes in real time. In addition, it calculates KPIs and

enables the creation of ad-hoc performance reports that can be shared

via the Web to help continuously improve production. The software is

beneficial for clients with a need for rich MES capability, but must

optimize investment and rapidly prove value due to limited

IT/Engineering resources, says the vendor.GE Intelligent Platformswww.gefanuc.com/smartstart800.433.2682