Synchronize Lean Material Flow

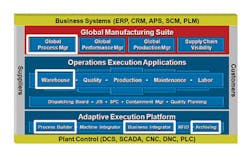

It is designed to better synchronize material flows, lower costs and

improve collaboration across operations. The solution fills some of the

“white spaces” or gaps around enterprise resource planning (ERP)

applications in Lean Manufacturing environments, says the vendor,

benefiting manufacturers who seek to reduce waste and cut cycle times

while improving quality in logistics operations, production and

customer responsiveness. The solution is said to synchronize material

flows spanning manufacturing operations to eliminate idle inventories

while delivering integrated quality execution and packaged logistics

with best-in-class label printing and “Poke Yoke” or error-proofing to

reduce manufacturing costs.Apriso Inc.www.apriso.com562.951.8000