Roping the Wind With OPC

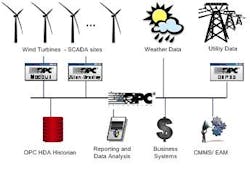

Roping the wind is an expression that means trying to do the impossible. It conjures images of taming something wild and unmanageable and bringing it under control. For wind farm operators, the challenge is not taming the wind. The challenge is getting vast amounts of data from geographically dispersed sources to the people that need it in a form they can use. MatrikonOPC has the people and products that can help wind farm operators to truly “rope the wind.”Typical wind-power developers, owners and service companies often manage multiple wind farms, across large areas, consisting of different turbine models from different companies. Asset owners need to be able to take basic measurements (such as production and power factors) as well as gather analysis data (such as temperatures and response times). In order to be competitive in the marketplace and meet critical time demands of power purchasers, wind-farm operators need to be able to quickly and reliably evaluate the electrical status of their parks.How OPC ropes the windOPC provides real-time data access for remote supervision, control, and data acquisition; this is required for operation and maintenance. It also enables standardized communication among energy management centers and regulatory bodies. OPC not only overcomes the challenges of gathering data from various sources, it also ensures guaranteed delivery of information regardless of manufacturers, technological generations or locations.MatrikonOPC provides OPC servers for common turbine protocols such as Modbus, as well as popular wind farm SCADA platforms such as those from Rockwell Allen-Bradley, Siemens and GE Fanuc. For connectivity with common electrical utility protocols like DNP 3.0 and IEC 60870-5, MatrikonOPC offers full telemetry-grade OPC servers that include redundant communication channel support.Changing winds and constant dataHistorized data from the wind farms is used for many functions including efficiency improvements, statistical process control, quality assurance and reporting. Storing the real-time process data allows wind companies to create genealogical records of processes, track equipment conditions and better forecast and schedule energy production. Reliance on this critical data requires a method to ensure data is not lost or corrupted during times of communication loss between the historian and the OPC server. OPC HDA specifications standardize how historical data is transferred. A guaranteed data delivery architecture using OPC HDA capabilities provides standard access to historical data, even during times of communication loss. It also offers increased flexibility on how and when the data is backfilled to the historian and can easily be duplicated to create a redundant solution. MatrikonOPC provides the means to manage wind farms in a standardized fashion by providing applications with real-time data and critical information on each point in the system. OPC products that gather high-resolution, real-time data give the end user far more capability to analyze the operation of the wind farm and OPC HDA technology guarantees the data is always available. With the right technology anything can be tamed; the wind and your data.For more information on solutions from MatrikonOPC, please visit www.matrikonopc.com