OPC Solves Building Automation System Integration Challenge

A building automation supplier was installing a system for a large medical lab. The system managed heating, ventilation and air conditioning (HVAC) control, lighting control, security systems and more. The challenge for this project was that there needed to be a touchscreen interface on each of floor of the facility. From each touchscreen, users needed to be able to access data for not only their floor, but for the other floors as well. Budget constraints meant the system had to be done as economically as possible.

The solutionBecause the building was already wired for Ethernet, it was easy to obtain an extra network jack at each panel. The building automation system provided an OPC server interface as a means of moving data into and out of the system.

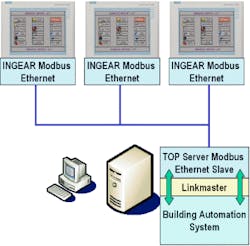

To move data between the remote panels and the building automation system, the integrator chose to use open Modbus Transmission Control Protocol (TCP) Ethernet protocol. This provided a fast and efficient means to communicate from the panels back to the Building Automation System over the existing Ethernet connections.

On each floor, a Siemens Windows CE Multipanel was installed, running an application using Siemens human-machine interface (HMI) software and an INGEAR Modbus Ethernet OPC server from Software Toolbox, based in Matthews, N.C. Back at the Building Automation System, the user installed a copy of the TOP Server Modbus Ethernet Slave driver and the LinkMaster OPC-to-OPC bridge. LinkMaster maps all necessary data from the Building Automation System to the Modbus Ethernet Slave. Each remote panel reads and writes data to and from the Modbus slave using the INGEAR Modbus Ethernet OPC server.

So how does it work? Let’s look at some examples. Remember, all these steps are happening in sub-second time over switched Ethernet.

In the first example—writing data from the touchscreen to the Building Automation System—when the user wants to write a value to the building automation system, the HMI software writes the data to the INGEAR Modbus Ethernet OPC server, which in turn writes the data to the TOP Server Modbus Ethernet Slave. The Modbus Ethernet Slave automatically notifies LinkMaster of the new value, and LinkMaster in turn writes the data into the Building Automation System’s OPC server.

In the second example—reading data from the Building Automation System and displaying it on the touchscreen—when values change in the Building Automation System, the Building Automation System OPC server automatically notifies LinkMaster of the new value. LinkMaster notifies the TOP Server Modbus Ethernet Slave of the new value. The INGEAR Modbus OPC server on the touchscreen is periodically polling the slave for new data. As soon as the new data is received, the INGEAR OPC Server notifies the HMI application, which updates the user’s screen.

For the user, the solution built with tools from Software Toolbox provided the results the client desired at an affordable price, with an open, standards-based solution achieving the desired level of performance. No closed or proprietary hardware was used in this solution, which gives the user the investment protection and the future flexibility desired.

For more information on OPC solutions from Software Toolbox, visit www.softwaretoolbox.com/opc.