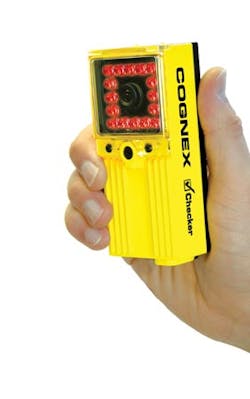

PLC-free Parts Inspection

The Checker 101E offers all the simplicity and power of the original Checker 101, plus it directly accepts encoder signals, eliminating the need for a PLC when tracking and rejecting parts on variable-speed production lines. “Unlike the shift register of a PLC, which requires programming, Checker’s shift register is automatic, enabling it to accurately track up to 4,000 parts between the inspection and rejection point,” says Brian Phillips, a vice president at the vendor. The Checker 101E can acquire and process more than 500 images per second.