OPC Speeds Line Assembly in Automotive Plants

"Forty OEMs from nine countries on three continents, delivering more than 250 production machines at a rate of one every 72 hours is a nightmare scenario," says Terry Weiss, Cyberlogic's account manager for a major U.S. auto manufacturer. "Yet, that is precisely how a new transmission line was scheduled to be assembled." In fact, this carefully planned and coordinated logistical challenge is standard fare for the U.S. automotive industry. In a beehive of activity, different sections of manufacturing lines—designed, produced and tested by original equipment manufacturers (OEMs) off site—are moved into place, bolted down and powered up in rapid succession.

"The individual machines can be tested mechanically, and the machine controls can be verified to a great extent at the OEM site prior to delivery," continues Weiss. "However, that is not true for the diagnostic data feeding the plant information systems." The plant's Information Technology (IT) department is unable to verify the validity of the diagnostic information until the machine is delivered to the plant. "And this is where the trouble begins," adds Weiss. "With only 72 hours between deliveries, there isn't sufficient time for the installation of the machine and the validation of the diagnostic information, let alone any corrective action."

The picture was even worse for another of Detroit's Big Three automakers. This time, the new engine plant was already in full production due to huge demand for its popular truck engines. The prime contractor and the OEMs had only 80 man-weeks to validate the operation of the plant information system across more than a thousand programmable logic controllers (PLCs). That's only three hours per PLC, an impossible task to perform manually. "The previous project [at another plant] went on forever," says Nicolas Dumortier, Cyberlogic's account manager for the automaker, "and neither the integrator nor the plant wanted another long project. It had to be done in 80 man-weeks."

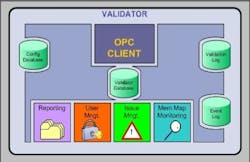

Both automakers turned to Cyberlogic, based in Troy, Mich., to provide an OPC-based tool for automated testing and validation of the diagnostic information. The result is Cyberlogic's Validator tool, an OPC client application. "The Validator is a time-saving test tool. Its goal is to certify that the implementation is in accordance with the specification," says Matt Zimmerman of Libert-E Systems, a consultant to the auto and bottling industries. "The Validator provides a formal context for testing with a repeatable, thorough and automated method," adds Zimmerman. It provides test reports, and features an issue management tool that allows the user to immediately report an issue during testing.

Using the Validator, the OEMs were able to verify the validity of the diagnostic data set of their machines prior to the delivery to the transmission plant. In the case of the engine plant, the integrator achieved 94.7 percent validation rate within the allocated 80 man-weeks. "The 94.7 percent validation rate is quite impressive," says Dumortier. "The remaining 5.3 percent was incomplete due to OEM unavailability."

The key to the success of the Validator is the use of OPC servers to extract the diagnostic information from the controllers. OPC, as an enabling standard, allowed an automated tool to be used across a wide variety of controllers, drives and Computerized Numerical Controllers (CNCs). Without the common interface OPC presents, all validation would have had to be done manually.

Cyberlogic OPC Server Suites are integrated, all-in-one products. The built-in reliability features allow the configuration of an unlimited number of redundant networks and backup data sources. Cyberlogic's OPC Servers include a Health Monitor that continuously verifies the operation of each network and data source, automatically switching to backups when there is a problem. The built-in unsolicited messaging feature allows the configuration of an unlimited number of nodes that can initiate unsolicited data transmission, eliminating the need for polling for data.

Cyberlogic is the leading independent supplier of industrial communication drivers and servers. More than 100,000 servers and drivers have been shipped worldwide by Cyberlogic and its OEM licensees since 1993. Find out more about the Cyberlogic Validator and OPC Server Suites at www.cyberlogic.com.