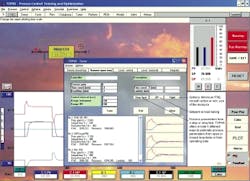

Optimize PID Tuning

In addition to the vendor’s proprietary method, highly recognized formulas including Astron, Cohen-Coon, Chien-Hrones-Reswick, IMC and ITAE have been included, some adapted. Tuning is calculated specifically for setpoint changes or load upsets, and users can opt for best performance, smoothest control action or minimum consumption of the resource. For the three best results, the loop behavior is presented graphically. Further testing and quick refining such as the effect of noise, sticking valves, process non-linearity or changes in the dynamics can be carried out with the integrated simulation environment.