Arla Foods Opts for Excellence

Arla Foods, the largest dairy company in Europe, receives around 7.2 billion kilograms of milk per year at its 70 plants in Denmark, Sweden and the United Kingdom, and develops approximately 200 new products annually. The company prides itself on providing the freshest milk products on the market through a concept called the “Arla Express,” which delivers milk from the cow to the grocery story shelf within 12 hours.

Like other successful manufacturers, Arla Foods continues to face price pressure from global markets, forcing constant reduction of production costs. Time-to-market and time-to-volume remain critical factors in meeting customer demands for increased complexity in product mix and timely supply.

Also like other manufacturers, Arla realizes that sustaining profitability and success in the marketplace is no longer just about controlling costs—it’s about speed. Arla Foods needs the ability to respond rapidly and cost-effectively to demand and supply variations, and at the same time understand how actual performance and current operational activities align with business objectives. But more than just reacting to changing market conditions or operational losses after the fact, Arla Foods needs the ability to exploit new opportunities for making profits before they vanish.

To achieve sustained profitability, Arla Foods, since 2002, has executed a global strategy called “One Arla,” with the objective of standardizing its business processes into a single system and integrating high-level business information systems with the plant-floor information systems.

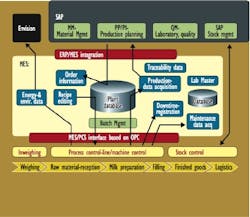

For the manufacturing operations, Arla needed to quickly duplicate its processes for milk, powdered milk and cheese across multiple plants with a common set of standards, in order to move information from the equipment and manufacturing processes all the way up to the enterprise resource planning (ERP) system. This would increase real-time visibility into all of the operations and improve planning and execution, while working within the existing infrastructures across the multiple plants.

Profit pressures

Pressures to improve production and profits exist at the local level and at the corporate level. Year after year, the local plants have had to deliver increased production profitability at equal or higher levels of quality, while still meeting budget constraints. They also have needed flexibility in terms of reduced time-to-market and time-to-volume to cope with the rapidly increasing complexity in product mix, due to private labeling and packaging. And they have had to comply with internal procedures for product quality documentation as well as government and institutional regulations designed to protect public health and safety.

Challenges at the corporate level have included: integrating global business processes with the company’s ERP system from SAP AG, of Walldorf, Germany; improving general profitability through better visibility into its diverse plants; leveraging best practices; using key performance indicators (KPIs) in a uniform way; reducing costs of ownership; adopting corporate standards; and implementing maintainable solutions from the plant floor to the business level.

To meet these challenges, Arla needed to adopt a low risk, scalable, reusable approach that could adapt to future requirements for processes, technology and people, while still keeping within local plant budgets. The main requirement was for users to have the ability to build upon their existing infrastructures without impacting their existing systems or disrupting production.

Centralized IT

Before the “One Arla” program was introduced, production information technology was defined locally at each plant. Now, all information technology functions have been combined into one central engineering support function called Production IT. Its task is to ensure that both the local plant and the corporate offices receive the information needed to improve production operations in each plant, and improve performance management across the enterprise.

The new Production IT group was given several ambitious goals. First, it needed to standardize on the SAP ERP to provide plant floor information integration based on market standards. All data collection, analysis and process optimization in the local dairy databases needed to be structured according to the guidelines established by the ISA-95 integration standard, promulgated by the Instrumentation, Systems and Automation Society (ISA). Implementation and roll-out used a scalable approach, in which slices of one solution could be reused and applied across different plants and systems.

Production IT also needed to build internal competencies in key areas and technologies involving both central and local resources. And it needed to establish a dialog with suppliers and internal staff, in order to share Arla’s strategic goals, drive increased adoption of market standards and continuously address issues of technology shortcomings.

Arne Svendsen, Production IT Manager at Arla Foods, stated in a recent interview, “The integration of business and manufacturing has a strategic importance for Arla Foods in supporting the challenges the business is facing in terms of optimizing production performance, as well as fulfilling food safety regulatory requirements. This integration includes the transfer of detailed production schedules from our ERP system to the plant floor, as well as the seamless collection of key processing and packaging figures. With an expansive growth strategy, it is a must to integrate business and manufacturing, especially when new facilities become part of the family due to mergers and acquisitions.”

A firm believer in standards, Svendsen has been influential in driving the adoption of market standards, and, in particular, the ISA-95 standard. For example, SAP recently announced full support for the ISA-95 eXtensible Mark-up Language (XML) standards using SAP’s Exchange Infrastructure (XI) based on NetWeaver technology. Svendsen’s team worked closely with SAP to ensure the successful evolution of technology that would meet the requirements of Arla Foods.

Industrial backbone

With Production IT on a roll, Arla wanted to continue momentum and take it a step further by integrating the local plants on a common industrial infrastructure. The company chose the ArchestrA infrastructure architecture technology and the Enterprise Integration Application from Wonderware , a business unit of Invensys based in Lake Forest, Calif., as the enabling solutions to provide the industrial backbone for all of Arla’s plants. The adoption of these technologies as corporate standards reduces costs by reusing engineering applications and standardizing equipment maintainability. As well, the Wonderware solutions can be scaled to meet local plant budgets and requirements.

Enterprise Integration Application adopts the ISA-95 standard called Business-to-Manufacturing Mark-up Language (B2MML) as the common message structure across the enterprise, enabling the maintenance of an integrated solution for a large number of sites. It also leverages the SAP NetWeaver XI to employ a highly standardized business-to-manufacturing solution with easier migration to future versions.

Because of the ArchestrA technology, Arla can standardize on manufacturing applications with a common manufacturing information infrastructure, while giving each plant the freedom to use specific solutions according to its needs. Wonderware’s production and performance management solutions increase the manufacturing capabilities in the SAP ERP to deliver a comprehensive solution for manufacturing operations.

While Arla’s approach is to re-use existing manufacturing execution systems (MESs), if applicable, Arla does make extensive use of other components in Wonderware’s production and performance solution to optimize its processes. These include the InBatch and InTrack for manufacturing execution; the Industrial SQL Server historian; the Active Factory trending and analysis tool; the Production Events Module for traceability; DTAnalyst for downtime and efficiency management; and the QI Analyst statistical process analysis and control software.

The combined approach reduces efforts and costs associated with designing, building, deploying and maintaining secure and standardized applications that support manufacturing operations. Using solutions from Wonderware and SAP to synchronize manufacturing operations with business objectives, Arla is getting the speed and flexibility it needs to achieve sustained profitability.