OPC Lowers Interface Costs for Building Automation

A building automation systems supplier needed to integrate several small, very low-cost touch panels into a building automation system. The touch panels offered a Modbus serial protocol master communications interface; however, the Building Management System (BMS) could only function as a Modbus master for connecting to remote devices. The possible solutions included writing a Modbus slave driver for the panels, or finding a way to put a Modbus slave interface on the building system. The building automation supplier called on applications engineers from Software Toolbox, based in Matthews, N.C., to help find a cost-effective, easily implemented, reliable solution to this challenge.

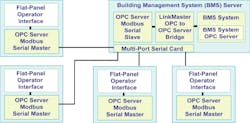

In investigating options, Software Toolbox’s engineers learned that the Building Management System had an OPC server interface that provided read/write access to the various points of interest in the system. The solution recommended by Software Toolbox and implemented in this application involved using Software Toolbox’s TOP Server Modbus Serial Slave OPC Server and LinkMaster OPC bridge.

Bidirectional data flow

On a personal computer (PC), the supplier installed a multi-port serial port board, and connected all of the touch panels to these ports using RS-422 connections, because of the distances involved. On the same PC, the TOP Server Modbus Serial Slave OPC server was installed and configured to listen for data requests from the touch panels connected to each serial port.

To bridge from the TOP Server Modbus Slave OPC Server to the Building Management System’s OPC server, the supplier used the Linkmaster OPC-to-OPC bridge. With LinkMaster, data points are mapped between the two OPC servers through a point-and-click interface, connecting registers in the Modbus slave connections to each touch panel and to the points in the building automation system. Once configured, data flows rapidly and reliably bi-directionally between the touch panels and the building automation system. Changes are easily made through a point-and-click user interface.

For more information on OPC solutions from Software Toolbox, including LinkMaster, TOP Server Modbus OPC Servers, and other building automation connectivity solutions, visit www.softwaretoolbox.com/opc.