Power Plant Upgrades Recorders

A large power plant initiated a program to replace existing Leeds & Northrup paper recorders with Yokogawa DAQStation video recorders. The initial justification for the upgrade was based simply on eliminating the cost of paper and pens. After installation, however, centralized access to the local data storage using OPC DA (Data Access) technology available for the Yokogawa DX recorders became an important feature of the system.

A plant-wide data historian software system was installed allowing data from the new DX video recorders, plus existing DR242 and HR2500 paper recorders to be integrated with other plant data sources in a central database.

The customer required video recorders with Ethernet networking that would replace the existing paper recorders. Given the wide range of support for OPC based products, the new recorders were required to support OPC. The goal was to make all recorder data available to the Aspentech data historian package via OPC. An additional plus would be the ability to link existing Yokogawa paper recorders into same data historian, so these existing recorders could continue to be used without further upgrade cost.

Faster speed, more reliable

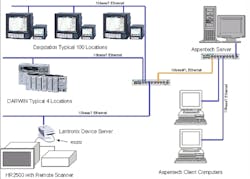

For primary data collection, Yokogawa recommended DAQSTATION DX video recorders with an OPC interface to the Aspentech historian software. Given the amount of information to be collected, the final installation will have approximately 100 DXs, four DR242 DARWIN chart recorders and 12 HR2500 chart recorders.

Yokogawa’s Kepware OPC server linked the DX and DR242 hardware to the Aspentech OPC client using OPC DA technology. The older HR2500 recorders were upgraded to RS232 communication and put onto the Ethernet network using Lantronix UDS-10 device servers. The device servers “encapsulate” the HR2500 serial communications within Ethernet.

The OPC server has the ability to access these device servers, which directly improves the speed and reliability of the link. Since the HR2500 recorders are not part of the standard OPC driver set, the Kepware UCON (User Configurable) driver software was used to quickly create a custom driver for the HR2500s. Connection of the numerous DX, DR242, and HR2500 recorders to the Aspentech historian was simplified through the use of Kepware’s Automatic Tag Generation function. The ATG function automatically determines the type of Yokogawa device located at a given drop and develops a tag database based on the configuration of that device.

The plant has a central server located in the primary computer room. This server monitors all of the data acquisition hardware. The server and data acquisition hardware are connected via 10baseFL and 10baseT network connections to hardware throughout the plant. The plant has PCs with client versions of the Aspentech software distributed throughout the plant for data viewing from any of these locations. Plant personnel can view heat rates, turbine vibration, bearing temps, water quality and other data in real time. Fast queries for historical data allow engineers to analyze past performance to aid in assessing current operating conditions.