Reconfigurable Controller Drives Advanced Manufacturing Research

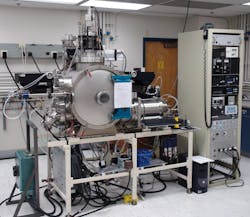

Cutting-edge research into thin-film semiconductor development, including the development of transparent thin-film transistors, transparent circuits, and high-performance thin-film based solar cells, is just a typical day’s activity at the semiconductor processing clean room at Oregon State University. Some of the tools used in the clean room include an RF magnetron sputter system, an ion beam deposition system, thermal evaporators, a chemical vapor deposition (CVD) system, and an electron beam deposition system. The university’s Advanced Materials Research and Development Program, which uses the clean room for its research, determined during a recent assessment that the electron beam deposition system needed to be replaced since it had been in use at the university since the early 1980s.

The electron beam deposition system is a useful tool for the program because it requires a relatively small amount of material (targets) to be deposited and yields high deposition rates. The replacement assessment for this system led to the design of a new electron beam deposition system that features a rasterable electron beam, substrate heating capable of temperatures up to 600°C, and base pressures approaching 1×10-7 Torr.

Included in the design of the new deposition system was an update of the system’s controls. Previous controls were built using microcontrollers and desktop computers with digital I/O cards. For the new system, a different approach was taken. This time a CompactRIO programmable automation controller was used for the core control system because of its reconfigurable nature and the ease of programming. CompactRIO’s control algorithm hardware implementation, in the form of an FPGA and embedded real-time controller, allowed for the new system to “accurately interlock and read electron beam conditions in real-time,” said Chris Tasker of the Oregon State University, Department of Electrical and Computer Engineering. “We also implemented a control program on the host PC so users can access database functionality and real-time system information.”

Tasker said the control logic was developed in LabView using the LabView FPGA module. “We wrote, tested, and debugged the FPGA and host code in about one working month,” he said. “This is much less time than required by previous systems that were coded in assembly language or Visual Basic.”

With the new electron beam deposition system in place, new functionality could be added as needed, such as PID substrate heat control. Tasker notes that, with CompactRIO as the core control system, “we were able to develop a new user interface with information and controls not previously possible; we were also able to incorporate advanced features such as e-mail notification and database logging to Microsoft Access into the host program.”

About the Author

David Greenfield, editor in chief

Editor in Chief

Leaders relevant to this article: