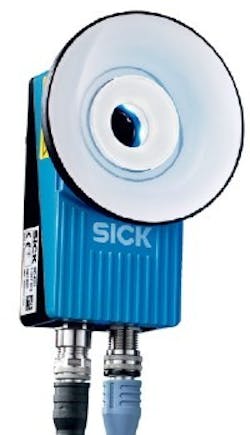

The "blob detection" tool works with objects that are less repeatable in shape, such as food picked from a belt. The user defines the "blob criteria," including pixel intensity, area, number of blobs (min/max) and the rotation angle. The series also allows for a "pass region," which allows a digital I/O signal to be triggered when a blob is in the correct position.The sensor also can offer a precise positioning point of a known target, using the X,Y and rotation angle of the taught part. Other benefits include "grip regions" with known objects, which allows the user to verify a part that is unobstructed and can easily be picked by an automated picking system. Other features include TCP/IP Ethernet communication, integrated lighting and interchangeable lenses. For complex applications, a dome light and color filters are options for difficult objects, such as metallic and shiny objects. SICK, Inc. www.sickusa.comMore information on position sensors on AutomationWorld.com.

About the Author

Grant Gerke

Digital Managing Editor

Sign up for our eNewsletters

Get the latest news and updates

Leaders relevant to this article: