Simplfy Flow Measurement

This multivariable transmitter improves productivity and makes energy management and environmental compliance easier. The Rosemount 3051SMV from Emerson Process Management simplifies mass and energy flow measurement, increases accuracy and provides faster updates through patented, advanced compensation techniques. The user enters three application parameters and the Engineering Assistant software handles the rest. The 3051SMV provides full compensation of over 25 different parameters to achieve a 5x improvement in flow performance compared to uncompensated differential pressure flow. This includes Joule-Thomson correction and sensor matching with Callendar-Van Dusen constants. The 3051SMV updates flow measurement 22 times per second so users can more effectively track production, demand, and total usage for process gas, steam, and natural gas. The results are more accurate billing, immediate detection of anomalies that lead to losses, and optimization of product throughput and quality during peaks in demand.

The Rosemount 3051SMV allows users to specify the level of compensation that best matches the application. It can be scaled to optimize flow measurement in four different applications:

1) Full compensation (differential pressure, line pressure, and temperature measurement) for gas, natural gas or steam

2) Differential and line pressure measurement for saturated steam

3) Differential pressure and temperature measurement for liquids or saturated steam

4) Differential pressure measurement for liquids at stable temperatures

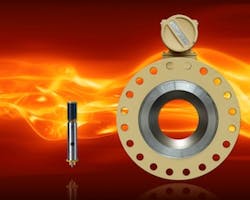

The 3051SMV transmitter can be paired with a Rosemount primary element, creating the 3051SF flowmeter. This flowmeter requires only a single pipe penetration for installation, minimizing costs in large line sizes. Annubar sensors create less blockage in the pipe than industry standard orifice plates, leading to an energy cost reduction in pumping, compression and fuel. The 3051SFC Compact Orifice flowmeter is easily installed between existing flanges with use of an integral centering ring and minimizes straight run requirements with conditioning technology. All Rosemount 3051SF flowmeters arrive fully configured, leak-tested and ready-to-install thereby reducing potential leak points and preventing fugitive emissions by up to 70 percent for better protection of the environment.