During the latest research we've been conducting on the market for motion controls, two key trends emerged from conversations with suppliers.

The first of these trends is the increased adoption of safety across industry. This is a general trend within industrial automation, but safety implementations still vary significantly by region. One of the key aspects of safety currently impacting motion control suppliers is the incorporation of certain safety features into servo drives, with safe torque off (STO) being the most common feature offered and used.

The push for safety has been led by the European market, and servo drives must incorporate STO to effectively compete in many European countries. However, suppliers continue to report sales of servo drives without STO in Eastern Europe and Turkey. In the Americas, STO has also evolved as a standard feature in servo drives, but STO is still seen as a way to differentiate products rather than as an absolute requirement, as it is in Western Europe. IHS conducted a special analysis on safety features for the 2013 Motion Control report and estimates that over 95 percent of servo drive unit shipments in 2012 were enabled with STO in EMEA compared with only 80 percent in the Americas.

In the Asian market (excluding Japan), STO is not a requirement and is typically only requested by machine builders who export machines to other regions. The difference in adoption of STO in Europe and the Americas compared to Asia is having the largest effect on Asian suppliers as they look to expand their business into other regions; a servo drive product with STO must be developed to effectively compete. STO is more commonly found in the Japanese market, with over 60 percent of unit shipments having this feature.

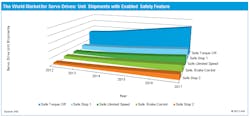

The servo drive market is also trending towards more advanced safety features, including safe stop 1 and 2, safe limited speed, safe speed monitor, and safe direction. Advanced safety features may be integrated into the drive, as STO is typically offered, or provided through optional safety hardware or software modules. IHS found that SS1 was the most common advanced safety feature enabled on servo drive unit shipments in 2012.

There are over 15 different safety features currently being incorporated into servo drives. Of course, each safety feature added to a drive or safety module increases the cost of that product. To balance demand for safety features with servo drive pricing strategies, suppliers of motion products face a difficult task in anticipating which features will have the highest future demand and deciding which (and how many) to pursue in upcoming product developments. As illustrated in the graphic accompanying this blog post (see image box in upper right corner of article), the number of servo drive unit shipments enabled with safety features is forecast to increase significantly from 2012 to 2017.

Another recent trend having a significant impact on the motion control market is the development of single-cable servo motors. Traditional servo motors use an analog feedback signal between the motor and drive. This analog signal is susceptible to electromagnetic interference and must be housed in a separate cable from the motor’s power source, resulting in two cable inputs for each servo motor. The need for two cables can be avoided by using an encoder that transmits feedback via a digital signal, which allows the power and feedback to be housed within a single cable.

This encoder technology has existed in the marketplace for some time, but over the past two years the number of servo motor suppliers offering a single cable motor solution has increased significantly. Because of its advantages, suppliers that currently offer a single cable solution are benefitting. The elimination of a cable and its connection results in cost savings with regards to materials and installation. Further, the digital feedback signal requires a much smaller number of terminations than the traditional analog signal, which simplifies wiring and increases the reliability of this connection. Despite the potential advantages of single cable servo motors, this trend is still in its early stages and many large suppliers do not yet offer this product.

Michelle Figgs is a senior analyst with IHS.

About the Author

Michelle Figgs

Senior Analyst, Industrial Automation, IHS

Leaders relevant to this article: