Understanding HMI’s Evolution Toward Easier Design

Human machine interface (HMI) design is so integral to our interaction with the machines we rely on to produce our goods that it’s no wonder HMI technology is of such perennial interest in the manufacturing sectors. From arguments over whether the gray look of high-performance HMI is more effective than the colorful screens that have dominated the past three decades of HMI technology to the mobile HMI screen design technologies used to monitor operations from anywhere on the planet, HMI continuously finds itself at the core of automation discussions.

Considering that the first HMI technologies were introduced 40 years ago, knowing how we arrived at the current state of HMI technology is one of the best ways to understand how the technology works as it does today, as well as where it’s headed.

HMI history

To start, let’s look back to the 1980s, when creating a graphical interface for machines required a programmable display unit together with programming software. “Before the advent of software created exclusively for HMI screen design, creating and designing an HMI required programming expertise and advanced computer knowledge,” says Manabu Kawata of Pro-face, Schneider Electric’s HMI division (supplier of the responsive Blue HMI screen design software).

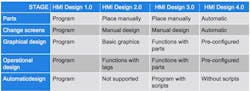

As a result, HMI development and maintenance at this time, which Kawata refers to as HMI Design 1.0, was time-consuming and expensive.

Then came the introduction of specialized HMI design software, which reduced the workload to create and maintain screens for the HMI. In this stage of HMI development, which Kawata calls HMI Design 2.0, there were two parts to the HMI design software. “First, a graphical component for drawing the screen display and, second, an operational component for programming screen operations,” he says. “The operational component required the set-up of special commands called screen tags. Configuring these screen tags still required some expertise and there was plenty of room for improvement in both design and operation.”

Then, in the 1990s, Microsoft introduced the Windows operating system, ushering in what Kawata calls HMI Design 3.0. “As industry embraced Windows software applications, HMI design began to integrate graphical and operational components so that you could simply change the properties or attributes of a graphical part to program your operations,” says Kawata.

“While expertise in HMI design, such as tag settings, became unnecessary and creating screens became much simpler, elements such as placing parts and changing attributes remained static for many years.”

He also notes that, even with all the advances that Windows brought to HMI design, the time requirements for HMI design were not reduced significantly.

Modern HMI

Today, Kawata sees industry as being in the HMI Design 4.0 stage due to the introduction of a range of new HMI design methods and concepts that have significantly reduced HMI design time. These new methods have eliminated many of the steps previously required for HMI design and introduced the ability to re-use previously created resources.

But the biggest factor influencing HMI design today is the smartphone, says Kawata. “Users now demand HMI screens that are clearer and easier to use,” just like their smartphones, he says.

In HMI Design 4.0, HMI layout screens offer a new method of design that’s quite different from the base screen design of past HMI design eras, largely because they're not dependent on HMI resolution. The concept of responsive screen design—which is common on websites so they can adjust from desktop to mobile device screen views—has come to HMI.

To understand how this applies to HMIs, Kawata offers a grid layout example (see the images above associated with this article). “The grid layout has rows and columns like a table,” says Kawata. When you draw an HMI part on the screen, you can then drop that part into a cell and that part will re-size automatically to fit into the cell area.

“The size of rows and columns on the grid is relative to the resolution of the screen,” he says. “If the screen resolution changes, the size of rows and columns adjusts accordingly. As a result, it is able to retain the location of parts relative to the original layout.”

Another advantage to HMI Design 4.0 is the ability to use templates with preset features and appearances.

“You can significantly reduce the time and effort of HMI design by using theme templates to give you the look and feel you want, color set templates to define the color tone, and navigation templates for screen changes,” Kawata says. “And, because you can change templates even after the HMI design is complete, you can make adjustments without disrupting the entire design.”

HMI screen design themes also allow for the changing of default values of part attributes and then registering those attributes for use in other parts. “For example, to set the font size for titles of parts to 20 points, which is larger than normal, you can edit the size of a part’s text font to 20 and save it as the default font size for titles,” says Kawata. “After that, changing the font size of parts is no longer required.”

Another benefit of HMI Design 4.0 software is that navigation templates automatically configure screen changes. “The design of change screen menus is set up in a template, and screen numbers for screen changes are configured automatically based on the screen structure. You can replace the navigation template to change the appearance of the menu; however, the screen structure does not change, [thereby] eliminating the need to review all of the screen settings,” says Kawata.

About the Author

David Greenfield, editor in chief

Editor in Chief

Leaders relevant to this article: