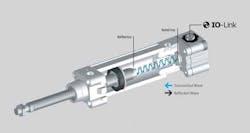

Developed by Festo AG & Co. KG, the Esslington, Germany based automation components and systems supplier, the technology relies on a microwave sensor that can be mounted within the end face of a pneumatic linear drive. In this position, the sensor can continuously measure piston position and speed across the entire cylinder stroke range, says Armin Seitz, head of Festo’s Sensors Business Unit. Operating in a frequency range of 1 to 24 gigahertz, the sensor works by using a tiny antenna that transmits electromagnetic waves into the cylinder barrel. These waves are reflected by the piston, and the returning waves are received by the same antenna and evaluated to determine piston position. “What we measure is the phase shift of the sent and received signal,” says Seitz. Target resolution for the technology is 0.1 millimeter (mm). Plug-and-workCompared to traditional approaches, the microwave sensing technology will offer several advantages for factory applications, Seitz says. Unlike externally mounted potentiometers or magnetostrictive sensors that require additional assembly and installation work—and thus extra costs—the integrated microwave sensor system requires none of that. The result, according to Seitz, is a simplified “plug-and-work” capability. “You just hook up your cylinder and you’re done.” Further, while traditional displacement encoders are available in discrete lengths, limiting the range of cylinders that can be used, the microwave sensor provides superior flexibility by working with any length cylinder. The sensor measuring length is unlimited and is governed automatically by the stroke length of the cylinder. And while initial Festo work has involved pneumatic cylinders, the technology will also work for hydraulics, says Seitz. “This sensor system is the first in the world to offer non-length dependent displacement measurement for pneumatic or hydraulic linear drives,” he declares. For factory users, these features will translate to advantages such as shorter commissioning times, less need for installation components and greater design freedom, which Festo says will drastically reduce the cost of applications.Additional industrial advantages include the microwave sensor systems’ electromagnetic immunity. “These sensors don’t see magnetic fields generated by motors, transformers or welding guns,” says Seitz. This makes the technology particularly well-suited for use in automotive welding applications, he believes. And because the sensors are enclosed within the aluminum housing of the cylinder itself, they will be less prone to mechanical destruction caused by bumps and jolts common in a factory environment, he adds. Besides automotive, Festo also sees particular value for the integrated sensor technology in the food and packaging industry. In this world, external sensors can be a hygiene risk, because their additional edges and corners act as food or dirt traps that are hard to clean. But by being “fully undercover,” as Seitz puts it, the integrated microwave sensors will eliminate these kinds of cleaning traps.As a still emerging technology, cylinders equipped with the integrated microwave sensing system have so far been provided only to “elite” Festo customers, Seitz says. But the company intends to develop the technology for “standard product” availability by 2008, he notes. Position data will be communicated via IO Link, an open sensor interface standard. Pricing on the microwave sensing technology is expected to fall below that of today’s traditional pneumatic position feedback solutions. That’s thanks in part to high-volume application of cellular phones and satellite technology, which has helped lower costs on components used in the microwave sensing system, Seitz explains. “At the moment,” he says, “the high frequency components are the most expensive parts.” But even those costs may be destined to decline. Festo’s current approach involves individual components mounted on a tiny substrate that is integrated into the cylinder cap. But eventually, Seitz indicates, the solution may be reduced to a single-chip design known as a MMIC, or microwave monolithic integrated circuit, which could further drive down costs.

About the Author

Wes Iversen

Managing Editor

Sign up for our eNewsletters

Get the latest news and updates

Leaders relevant to this article: