Food and Beverage Automation Set to Grow

Driven by new regulatory requirements in a post-9/11 world, the global market for automation products used by the food and beverage industry is expected to grow at an accelerated rate during the next several years, according to a recent study from research firm Frost & Sullivan.

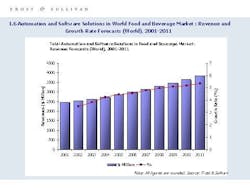

The study, titled “Automation and Software Solutions in World Food and Beverage Market,” projects that revenue in these markets will grow from $2.74 billion in 2004 to $3.83 billion in 2011.

Following the terrorist attacks of Sept. 11, 2001, the U.S. Congress passed the Public Health Security and Bioterrorism Preparedness and Response Act of 2002, requiring manufacturers to be able to track and trace their products, including their key ingredients and suppliers. Similar legislation was enacted in Europe. Additional regulatory revisions by the U.S. Food and Drug Administration (FDA) require food manufacturers to provide greater production transparency through audit trails and access control functions.

These regulations are likely to enhance the need for automation solutions in the food and beverage industry, Frost & Sullivan says. In addition, the promise of better visibility into the production process is seen as an added driver spurring demand for these solutions.

“In the past, plant operation data was available only to the shop floor personnel, and top management had little idea about the status of plant operations,” says Frost & Sullivan Research Analyst Sandeep Hassan Rangaswamy. “By implementing manufacturing execution systems (MES) and industrial asset management solutions, all the products and processes, including maintenance activities, can be tracked efficiently, thus improving operational efficiency and reducing lead times and waste.”