Honeywell Brings Virtualization to Blade Servers for Process Industries

As process industries look for ways to save money and optimize operations, an increasing number are looking to virtualization. By abstracting systems and applications—virtualizing hardware devices—a single server can run multiple operating systems and applications simultaneously, insulating virtual machines from each other and the hardware.

Honeywell introduced virtualization to industrial control systems in 2010 to help processing plants and refineries simplify their computing environments, streamline maintenance and reliability, and reduce the amount of hardware space needed at facilities such as offshore oil rigs.

Now Honeywell has launched the industry’s first turnkey blade solution that is optimized for virtualization and the needs of the process control industry. The Experion Virtualization Solutions package enables offshore oil and gas, refining and petrochemical customers to increase operations availability and reduce the total cost of ownership of their control system, saving them millions of dollars annually.

Process controls typically require separate servers to support different applications—requiring additional space, hardware and significant maintenance costs. Virtualization insulates operating systems from hardware changes, improving overall server utilization, simplifying maintenance and reducing costs.

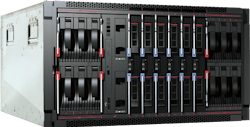

Based on blade server technology from IBM, the Premium Platform provides an alternative for lifecycle and availability features being demanded by process industries. It reduces setup time by 90 percent, generates 40 percent more energy savings, has 22 percent greater density than alternative virtualized server platforms, and allows recovery from a processor failure in minutes.

“Customers are demanding higher availability from their virtual environments,” said Jason Urso, vice president of technology, Honeywell Process Solutions. “Virtualization solutions using blade servers offer that extra layer of reliability, but it’s about more than just reducing downtime. Virtualization simplifies operations and allows manufacturers to modernize their facilities and turn them into true business assets.”

Learn more about virtualization at Honeywell’s website.

About the Author

Aaron Hand

Editor-in-Chief, ProFood World

Leaders relevant to this article: