From innovations such as the Internet of Things to smarter robots, embedded technologies are already having an impact on today’s automation technologies. But these embedded technologies are not only having an impact in cutting edge areas like the Internet of Things. They're also impacting everyday automation devices such as drives and inverters.

One of the more recent examples of this is the new C2000 Delfino 32-bit F2837xD microcontroller (MCU) from Texas Instruments. This new MCU has dual-core C28x processing capabilities and dual real-time control accelerators, also known as control law accelerators, meaning that these new MCUs provide 800 MIPS of floating-point performance, enabling the development of low-latency systems in computationally demanding control applications.

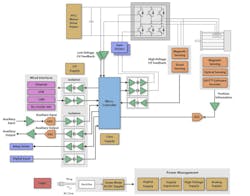

The capabilities of this new MCU allows for the consolidation of multiple embedded processors into a single MCU for applications requiring real-time signal analysis, such as high-end servo drives, solar central inverters, and industrial uninterruptable power supplies (UPS).

Multiple feedback inputs can be simultaneously controlled and monitored with the Delfino F2837xD MCU, says Texas Instruments, via the use of analog peripherals integrated on-chip. With four independent 16-bit analog-to digital converters, the F2837xD MCU can manage multiple analog signals, thereby enabling overall system throughput for applications such as the monitoring of three-phase motors.

Critical power stage protection offered by the MCU allows them to be used to safely shut down motors via the chip’s integrated windowed comparators. In addition, the MCU’s sigma delta demodulators allow direct interface to isolated converters providing noise immunity for the MCU.

Other features of the Delfino F2837xD MCU include:

- Execute trigonometric-based algorithms used in control functions, such as torque loops traditionally done in FPGAs with the new trigonometric math unit accelerator included on the C28x cores.

- Better predict motor failures by performing vibrational analysis with the viterbi complex unit (VCU II) accelerators, which boost processing capabilities in the C28x cores.

- Fine-tune, control and monitor multiple feedbacks using four 16-bit ADCs to improve system accuracy.

Leaders relevant to this article: