Intelligent instruments aren’t nearly so smart when they can’t communicate their information with each other. So Field Device Technology (FDT) has for several years been an open interface used to integrate field devices of all different colors and flavors.

With a 10+ year track record and now more than 90 process and factory automation companies participating in the FDT Group, FDT is gaining popularity as a device interoperability standard, recognized worldwide within IEC 62453, ANSI ISA 103, and more recently China GB/T 29618 standards.

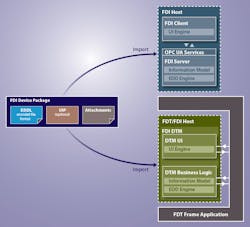

At the Yokogawa Users Conference this week in Houston, the FDT Group discussed the next step in integration, both at its booth and in a technical presentation by Chuck Micallef. Whereas FDT uses a device type manager (DTM) to make it easy for devices to communicate with each other, Field Device Integration (FDI) is a fully functional device package, including the Electronic Device Description Language (EDDL), a user interface plug-in, and also attachments like certificates, data sheets, manuals, etc.

The FDT standard works in much the same way as HART, for example, or Foundation Fieldbus. “It’s standardizing the way we look, talk and address intelligent field devices,” Micallef said. Describing the use of smart instruments particularly in dangerous processing locales, he added, “We can get the information back to a remote, clean, hopefully safe location. Let’s find out what we can find out from these intelligent devices before we go out.”

Now the FDT Group has teamed up with the HART Communication Foundation, Foundation Fieldbus, Profibus & Profinet International, and OPC Foundation to develop this single common FDI solution. “It’s a soon-to-be-released standard, and you can expect to see devices in late 2015, maybe 2016. It covers EDDL-based networks like HART, Foundation Fieldbus and Profibus,” Micallef said. “It provides a single file for the user containing everything he needs. It includes all the information you need to support a device.”

FDT, Foundation Fieldbus, Profinet, Profibus and HART all use EDDLs. “If you use one of those, FDI can help solve your problem,” Micallef noted. However, he added, if you’re using any of the many other buses out there, you might want to stick with FDT.

If you haven’t yet made the move to FDT, there’s no reason to wait for even better FDI standard, Micallef said. Many DTMs can go into an FDT host, but so can an FDI DTM, incorporating FDI device packages. “So there’s no reason to delay going to FDT now,” he said. “You can still use it with FDI in the future.”

Get more information about both technologies at the FDT Group and FDI Cooperation sites.

Leaders relevant to this article: