As more manufacturers take advantage of the increasing capabilities for a connected world, they are looking to escape the confines of vendor-specific data exchange protocols. PLCopen took the occasion of Pack Expo earlier this month in Chicago to showcase how its members in packaging and processing industries are using PLCopen OPC-UA based standards for their controllers.

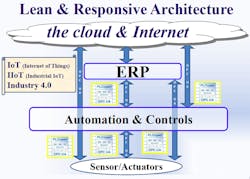

PLCopen is a platinum member of the Pack Expo Partner Program, and partnered in the tradeshow, demonstrating how the new open industry standards simplify Internet of Things (IoT) type communications between sensors and enterprise, Cloud and Internet with PLCopen web services function blocks based on the OPC-UA standard.

The function blocks are also defined for direction machine-to-machine (M2M) communications between multiple vendor controllers to coordinate automation. This simplifies the integration of production, process control, packaging and other machines into more efficient system architectures.

At a press conference at Pack Expo, PLCopen also shared a couple success stories outside the packaging realm, including smart metering for energy management and M2M communications for intelligent water management.

In the first case, IT service provider regio iT implemented e2watch at about 170 facilities in the region around Aachen, Germany—including schools, daycare centers, office buildings, sports facilities, swimming pools, museums and commercial spaces—to monitor electricity, water and heat usage. e2watch, based on advanced data logging technology from Beckhoff Automation, collects measurement data that is then synchronized and evaluated, and detailed energy consumption reports are made available through a web portal.

The connected buildings represent about 1,030 data points collected in 15-minute intervals, totaling about 100,000 records a day. Beckhoff’s data logger uses the standard PLCopen OPC-UA client function blocks, which enables the device to actively initiate secure communications and push collected information into the Cloud as well as retrieve configuration data.

The e2watch system uses a compact controller as a decentralized control unit for data acquisition and buffering. The core of the data logger is a CX series embedded PC running TwinCAT 3 automation software. A KL6781 M-Bus master terminal is used to integrate the meter into the controls platform.

Similar technology is used to control potable water and wastewater plants for the Joint Water and Wastewater Authority, Vogtland (ZWAV) in Germany. OPC-UA is integrated into some of the smallest Beckhoff controllers, CX9020 embedded PCs, to provide intelligent networking between plants through the decentralized, independently acting controllers.

ZWAV has about 300 potable water plants and 300 wastewater plants (pumping plants, waterworks, elevated reservoirs, etc.) distributed over 1,400 km2 and covering 40 cities and 240,000 people. Real models such as pumps were modeled in the TwinCAT IEC 611313 PLC software from Beckhoff as complex objects with interactive possibilities. The integrated OPC-UA server makes the objects automatically available to the outside world as complex data structures for semantic interoperability.

The result is decentralized intelligence, where devices can make decisions independently and can transmit information to neighboring systems. In addition, it can query equipment status and values for its own process in order to ensure trouble-free process cycles.

According to ZWAV, the replacement of a proprietary solution with a combined OPC-UA client/server solution provided savings on the initial licensing costs of more than 90 percent per device. Minimizing service assignments in the field results in significant additional savings. Better standardization also results in more efficient engineering, cost reductions, reuse of technology/equipment, improved transparency, increased availability, increased choice of providers, and higher interoperability.

About the Author

Aaron Hand

Editor-in-Chief, ProFood World

Leaders relevant to this article: