This post centers around new findings coming out of the

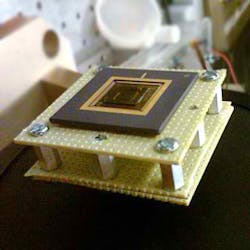

Massachusetts Institute of Technology (MIT) on microelectromechinaical

systems, or MEMS. Energy harvesting has been a very interesting topic of conversation within manufacturing because it supposes that mechanical vibrations from motors or other industrial equipment can produce a consistent energy source for other devices. For example, wireless sensors networks could be powered by vibrations from a pipeline in the field, instead of battery power. That's been a big issue in the adoption of wireless sensor networks.

Past developments with energy harvesting have relied on piezoelectric (PZT) technology or multiple PZT layers on a microchip. However, PZT technology depends on mechanical vibrations within a certain frequency and outside of it, no power can be

generated. Some have pushed for more "layers" on a chip to pick up more

vibrations (or more energy), but that drives up costs and sensors need to be inexpensive for large deployments.

These new MIT findings see a design that increases the device's

frequency range or bandwidth, while maximizing the power (energy) density. MIT researchers put it through a series of vibration tests and have calculated

that the device was able to generate 45 microwaves of power with just a

single layer of PZT--an improvement of two orders of magnitude compared

to current designs, says MIT.

The MIT team published its results in the Aug. 23rd online edition of Applied Physics Letters.

>> Click here to read the MIT ENERGY-harvesting research paper.

About the Author

Grant Gerke

Digital Managing Editor

Sign up for our eNewsletters

Get the latest news and updates

Leaders relevant to this article: