Manufacturing companies of all sizes are constantly seeking ways to reduce costs. Much of this cost-reduction focus tends to fall on production-related activities ranging from throughput to labor. As a result, other less-obvious areas for significant cost reduction can go unnoticed.

According to IHS, an information and analytics provider, one of these overlooked areas tends to be MRO (maintenance, repair and operations) master catalogs.

IHS research indicates that some 55 percent of MRO inventories have not moved in the past three years; 30 percent of MRO inventories currently in stock will never be used; and 6 percent of MRO items make up 90 percent of companies’ annual MRO spending.

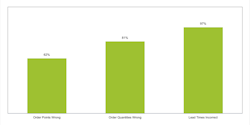

Compounding the problem, according to IHS, is that the majority of reorder points, quantities and lead times are incorrect (see graphic). As a result, an estimated 62 percent of MRO orders points are wrong—with 81 percent and 97 percent of order quantities and lead times being erroneous

“Companies must recognize the importance of solid MRO foundational data and understand the correlation this has to other areas of their business,” says John Ferguson, certified maintenance and reliability professional for the IHS Supply Chain service. “Once they get the foundation right, other related goals or initiatives in operational excellence will be much easier. The lack of emphasis on MRO data quality results in inefficiency. Organizations waste an inordinate amount of time and resources trying to make other pieces of the MRO lifecycle work with master data that ranges from being poor in quality to downright toxic.”

To illustrate his point, Ferguson notes a real world example spotlighting the MRO data issue around a single MRO part—a ball valve. This ball valve was described in six different ways within the company’s MRO master catalog. Ferguson notes that the same part had multiple records with different descriptions, part numbers and prices.

“These types of catalog inconsistencies prevent companies from locating required parts for scheduled and unplanned maintenance work. When parts cannot be located, companies purchase excess parts, causing inventories to balloon,” Ferguson says.

To prevent such negative ramifications on operations—and to leverage MRO data in support of corporate-wide initiatives that can improve efficiency—companies must put their MRO data into an accurate, consistent and structured format, free of duplicate parts.

However, this process only serves as the basis for other steps that companies must take to get engaged in MRO best practices. Following the process of optimizing MRO data, companies must adopt a sustainable MRO data-governance model along with enabling technology that seamlessly integrates into their enterprise resource planning (ERP) and enterprise asset management (EAM) systems to dynamically synchronize their MRO data

Next, companies should optimize MRO inventory. This can lead to more balanced inventory levels, and allow companies to conduct criticality analysis and make impact assessments.

Finally, Ferguson says that companies need a systematic approach for classifying, managing and optimizing all aspects of their MRO value chain, including MRO materials master catalog data management, strategic sourcing, procurement, critical spares identification, balanced inventories, asset dispositioning strategies, and inventory and storeroom best practices.

About the Author

David Greenfield, editor in chief

Editor in Chief

Leaders relevant to this article: