As noted in a study a couple months ago, Coriolis flowmeters dominate revenue numbers in the petroleum liquid industry. Not so for magnetic flowmeters, whose main limitation is their inability to measure hydrocarbons. They are used to measure the flow of conductive liquids and slurries, including pulp and paper slurries and black liquor. Since hydrocarbons are non-conductive, magnetic flowmeter are avoided for petroleum.

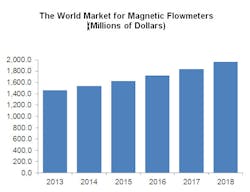

But despite their disuse in one of the hottest markets today, magnetic flowmeters generate more revenues worldwide than any other type of flowmeter, according to a new study from Flow Research. Revenues from magnetic flowmeters exceed revenues from all other flowmeter types, including Coriolis, positive displacement, turbine and differential pressure (DP) meters.

Most flowmeters—including turbine, Coriolis, ultrasonic transit time and vortex meters—do their best work in clean liquids or gases. Magnetic flowmeters, on the other hand, thrive on dirty liquids. Magnetic flowmeters and Doppler ultrasonic meters are the only two of the main types of meters that do well in dirty and impure liquids, although DP meters can also measure dirty liquids if they have the right kind of primary element.

Although the magnetic flowmeter market is a mature and stable one, some new product developments in the magnetic flowmeter market favor continued growth. One recent development is the advent of two-wire magnetic flowmeters. Four-wire meters have a dedicated power supply. Two-wire meters use the power available from the loop-power supply. This reduces wiring costs, and can result in lower installation costs, making them more popular with users. Two-wire meters still represent only a small percentage of the total magnetic flowmeters sold, but their use grew significantly from 2008 to 2013.

Another important development is growth in battery-operated and wireless magnetic flowmeters. Battery-operated meters make it possible to install magnetic flowmeters in hard-to-reach places. And wireless meters can transmit a receivable signal where the use of wires is impractical. Both of these segments represent fast-growing areas of the magnetic flowmeter market.

Magnetic flowmeters will increasingly be seen as an alternative to differential pressure flowmeters. They are widely used in the process industries, including chemical, food and beverage, pharmaceutical, and pulp and paper industries. In the food and beverage and pharmaceutical industries, for example, special liners enable them to be used in sanitary conditions. Some 29 percent of magnetic flowmeter revenues are from sales to the water and wastewater industry, which has the highest percentage of magnetic flowmeter sales of any of the process industries.

Multiple factors are driving the magnetic flowmeter market, according to Jesse Yoder, president of Flow Research:

- A steady stream of new products has kept the magnetic flowmeter market dynamic.

- The development of insertion meters gives more options to end users who may hesitate to pay the high prices for large line size magnetic flowmeters.

- Suppliers have brought out a wide variety of liners to handle sanitary and caustic liquids.

- Advanced diagnostics are making magnetic flowmeters both more intelligent and more reliable.

- Water flow measurement is increasingly important as populations within countries increase and water shortages become more common.

About the Author

Aaron Hand

Editor-in-Chief, ProFood World

Leaders relevant to this article: