In the world of automation, we all know what a sensor is—in all its various forms. But how do you sense something without a sensor? This question may sound like a riddle but it’s actually a new type of sensing approach announced by Frauscher Sensor Technology at InnoTrans 2016 in Berlin.

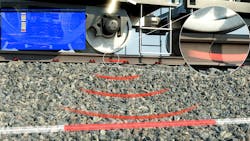

Here’s a snapshot of how it works: Located alongside all railway tracks is fiber optic cable used for various communication purposes. Due to its close proximity to the tracks, this cable can pick up vibrations emitted by anything on or near the tracks — whether it's a train, workers, or even a flock of sheep. Spare capacity on the fiber optic lines is used to detect vibrations via acoustic sensing. The key to the technology introduced by Frauscher is that it can not only sense the difference between sources of vibrations, it can determine what they are and send notifications appropriately.

According to Michael Thiel, Frauscher CEO, the key to the company’s technology is an algorithm that can determine what these different vibrations are. This ability to translate vibrations into specific object identities extends to the point of knowing the exact location, speed and direction of a train on the tracks; it can even determine if the vibrations are emanating from two trains going in different directions.

Frauscher partnered with Fotech Solutions to deliver the Frauscher Tracking Solution (FTS). Fotech’s expertise is in the use of digital acoustic sensing (DAS). According to Fotech, its DAS sensing technology converts standard communications fiber into a linear array of discrete vibration sensors. Beyond train monitoring, DAS can be applied to oil and gas pipeline operations to detect hot tapping or leaks, monitor fracking operations in oil wells, and provide perimeter intrusion detection.

The technology is currently being used at Frauscher’s test site near Schärding, Austria.

FTS monitors the cable 2,500 times per second to provide its detailed information. Data collected by the FTS is displayed on a visualization screen that shows on-time trains in green and late trains in red, as well as other data about the trains.

Peter Bradley, FTS director, stresses that a key aspect of this technology is that it requires no hardware to be installed along the railway, so there is no field equipment to maintain. The only equipment is the FTS cabinet, which is housed centrally in a control room. Each FTS can monitor up to 40 km of rail.

“It's not just what you can detect,” said Bradley, “it’s what you can do with the continuous tracking information about the train. Many applications will be built for this kind of sensing technology data.”

About the Author

David Greenfield, editor in chief

Editor in Chief

Leaders relevant to this article: