Brushless Motor Helps Steer Dragon to Space Station

It’s hardly news that the tools often used for manufacturing automation, such as sensors, motors and actuators, are used in high profile applications such as space travel. But knowing the type of equipment you work with on a day-to-day basis is out there on the frontier of advanced technology rarely ceases to spur interest and imagination.

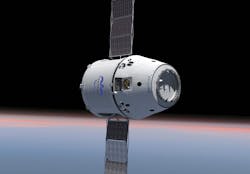

Such was the case with the launch of the SpaceX Falcon 9 rocket on May 22, 2012. This event marked the launch of the first private cargo capsule — the unmanned “Dragon" spacecraft — in the history of space travel. Not only was it the first private cargo capsule launch, but it also marked the first time a private company developed a combined spacecraft and launch system capable of undertaking an orbital rendezvous and then returning to earth. The capsule was designed to deliver materials to and from the International Space Station (ISS) — the only means of doing so from the U.S. since the cessation of the Space Shuttle program.

The Dragon spacecraft (14.44 feet in height) was used to supply nearly 1200 pounds of scientific equipment and food to the ISS. On May 31, the six-ton Dragon capsule was detached from the ISS and splashed down in the Pacific Ocean, returning nearly 1500 pounds of material from the ISS.

Maxon’s brushless motors were used to rotate Dragon’s solar arrays to keep them aligned with the sun as the spacecraft orbited the earth after launch. The motors were also used to open the instrument bay door, which contains navigation equipment, and lock in place the fixture that allows Dragon to be grappled by the space station’s robotic arm.

Read more Automation World coverage of SpaceX's Dragon capsule and Falcon rocket.